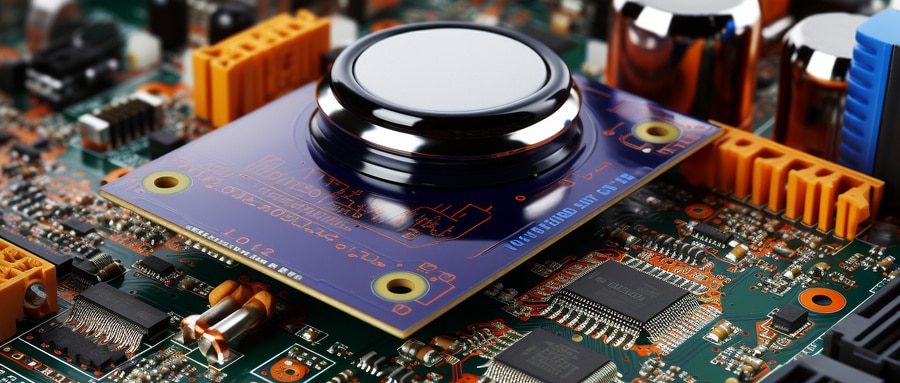

The Intricacies of an 8-Layer PCB Stackup: An Exhaustive Guide on its Design and Benefits

An 8-Layer PCB Stackup stands out as an optimal choice for high-density applications that require intricate routing spaces, superior EMI shielding and signal integrity improvements. This comprehensive guide aims to untangle its complex nature, while offering insights into its structure and advantages.

The Framework of an 8-Layer PCB Stackup

Understanding how an 8-Layer PCB Stackup operates is vital to grasping its operational excellence. At its core, this structure comprises eight conductive planes connected by insulation layers stacked in compact multilayer form.

An 8-Layer PCB stackup typically comprises four plane layers and four signal layers, providing optimal EMI shielding by positioning signal layers between power and ground planes.

Benefits of an 8-Layer PCB Stackup

8-Layer PCB Stackup designs offer several advantages that make them the go-to option for complex electronics projects.

- Enhanced Signal Integrity: By employing alternate ground and power planes in its stackup, PCBs can reduce crosstalk while creating a solid ground return path, leading to improved signal integrity.

- Enhanced EMI Shielding: By strategically placing signal layers amidst power and ground planes, enhanced electromagnetic shielding can be provided, thus decreasing potential interference issues.

- Enhanced Depth for Routing: With eight layers for signal and power routing, an 8-Layer PCB Stackup can accommodate the complex circuitry required in dense electronic systems.

Design Considerations for an 8-Layer PCB Stackup

Establishing a reliable and cost-effective 8-Layer PCB Stackup requires an intensive design process with careful attention being given to:

1. Balanced Construction: An optimal stackup helps minimize internal stress, thus limiting board warping during assembly.

2. Efficient Heat Dissipation: By including thermally conductive planes in the stackup, effective heat dissipation can be achieved for power-intensive applications.

3. Impedance Control: For multilayer designs, controlling impedance becomes critical to maintaining signal integrity, necessitating precise control of board parameters including width, thickness, dielectric constant and more.

Applications of 8-Layer PCB Stackup

8-Layer PCB Stackup’s unique value proposition finds its place in various high-end, critical applications ranging from computer and telecom systems, industrial controls, medical devices and space and military hardware.

An 8-Layer PCB Stackup’s dynamic features, combined with superior EMI shielding and signal integrity capabilities, underpin its value in complex electronics design. As electronics continue to miniaturize while increasing in complexity, multilayer PCBs such as 8-Layer PCB Stackup are expected to become increasingly prevalent in designs of increasingly complex electronics products.

Understanding an 8-Layer PCB Stackup reveals one of the many marvels of modern electronics design. Boasting intricate designs, enhanced performance, and varied applications, multilayer PCBs not only demonstrate technological progress; they open up an incredible spectrum of opportunities demonstrating electronic designs’ ever-evolving nature. As we move into the future we can expect even more innovations to propel electronics even further forwards.

FAQ:

- Q: What is an 8-layer PCB stackup?

A: An 8-layer PCB stackup refers to the arrangement of copper layers and insulating layers in an 8-layer PCB. It typically comprises of 8 copper layers, 7 insulation layers, solder mask, and silkscreen. - Q: Why would I choose an 8-layer PCB over a simpler stackup?

A: 8-layer PCBs can provide more routing space, better electromagnetic interference (EMI) control, and improved signal integrity compared to simpler stackups. They are often used in complex electronic equipment. - Q: Is an 8-layer PCB more expensive to manufacture?

A: Yes, due to the more intricate process and increased material usage, an 8-layer PCB is typically more expensive to manufacture than a board with fewer layers. - Q: What is a typical application for an 8-layer PCB?

A: Typical applications include advanced computer systems, telecommunications equipment, aerospace technology, and complex industrial controls. - Q: What is the benefit of using plane layers in an 8-layer PCB stackup?

A: Plane layers can help distribute power and ground connections more evenly across the board, reduce EMI, and improve signal integrity. - Q: How long does it take to manufacture an 8-layer PCB?

A: The time can vary depending on the complexity of the design and the manufacturer’s capabilities, but it is generally longer than the time required for a simpler, fewer-layer PCB. - Q: How is signal integrity managed in an 8-layer PCB?

A: Signal integrity is typically managed by properly arranging the signal and plane layers, as well as implementing careful routing strategies to minimizes cross-talk and signal noise. - Q: Can I design an 8-layer PCB myself?

A: While it’s possible, designing multi-layer PCBs like an 8-layer PCB requires advanced understanding in PCB design and EMC principles. It might be beneficial to work with experienced designers or engineers. - Q: What is impedance control in an 8-layer PCB?

A: Impedance control involves designing the PCB to maintain a consistent impedance across the signal lines, which is critical for the performance of high-speed digital circuits. - Q: What are the challenges in fabricating an 8-layer PCB?

A: Challenges include maintaining the correct alignment of each layer, ensuring that each layer’s electrical characteristics match the design requirements, and managing complex via structures.