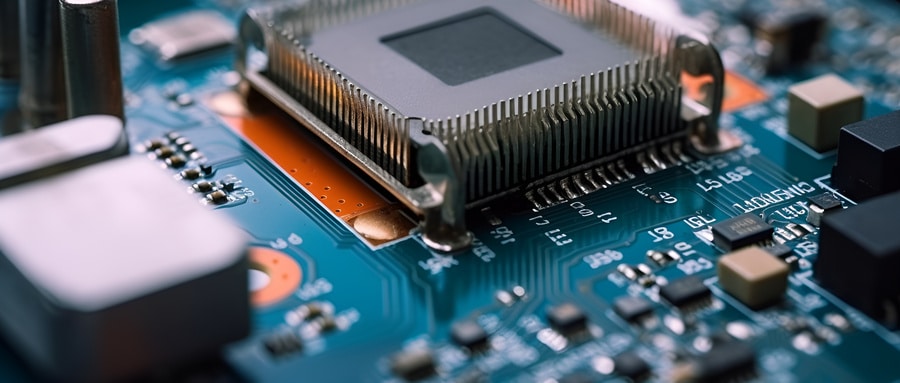

Exploring FR4 PCBs – The Versatile and Reliable Choice for Electronic Circuitry

When discussing electronic circuit boards, the term FR4 often comes up. This substrate material is commonly used for manufacturing printed circuit boards (PCBs). We will explore this world of FR4 PCBs here by exploring their composition, properties, advantages and applications – so you can make informed decisions when it comes to your electronic circuitry needs.

1. What Is FR4?

- Composition: FR4 is a flameproof glass-reinforced epoxy laminate material consisting of an impregnated fiberglass cloth impregnated with an epoxy resin binder.

- Flame Retardancy: One of the primary features of FR4 material is its flame retardancy, designed to resist fire spread in electronic applications and add another layer of protection against it.

- Glass Reinforcement: Woven fiberglass cloth provides mechanical strength and rigidity to FR4 PCBs, making them resilient against various stresses and environmental conditions.

2. Properties of FR4 PCBs:

- Electrical Insulation: FR4 boasts excellent electrical insulation properties, making it the ideal material to create isolation layers on PCBs.

- Thermal Stability: FR4 has outstanding thermal stability, enabling it to withstand elevated temperatures encountered in soldering processes or high-temperature environments without melting.

- Mechanical Strength: The glass reinforcement found in FR4 PCBs gives them mechanical strength, assuring durability and resisting bending or warping.

- Dimensional Stability: FR4 PCBs feature excellent dimensional stability, meaning they retain their shape and size despite temperature variations or moisture exposure.

- Dielectric Constant and Loss Tangent: FR4 has an extremely low dielectric constant and loss tangent, providing efficient signal transmission while decreasing signal distortion.

3. Advantages of FR4 PCBs:

- Wide Availability: FR4 PCBs are easily accessible on the market, making them cost-effective and accessible solutions for various electronic projects.

- Versatility: FR4 PCBs offer exceptional electrical and mechanical properties, making them suitable for a range of uses from hobby projects to complex industrial electronics applications. Their adaptability owes much to this feature of their composition.

- Compatibility With Components: FR4 PCBs can accommodate various kinds of electronic components, including through-hole and surface mount devices, making them compatible with diverse circuit designs.

- Design Flexibility: FR4 allows for precise PCB fabrication with intricate layouts and tight tolerances that enable designers to optimize their circuit designs while taking full advantage of space utilization. This makes FR4 ideal for optimizing space utilization in circuit design projects.

4. Applications of FR4 PCBs:

- Consumer Electronics: FR4 PCBs have found wide application in consumer electronics products such as smartphones, laptops, gaming consoles and home appliances due to their reliability and cost-efficiency.

- Automotive Electronics: FR4 PCBs have become popular choices for automotive applications such as engine control units, infotainment systems and safety systems due to their ability to withstand extreme temperatures and environmental conditions.

- Industrial Electronics: FR4 PCBs are frequently employed in industrial automation, power distribution systems, control panels and robotics where their durability is key to operation.

- Telecommunications: FR4 PCBs play an essential role in supporting telecom infrastructure, helping transmit and receive signals in routers, switches and communication equipment.

- Aerospace and Defense: FR4 PCBs have many applications within the aerospace and defense industries, including avionics systems, navigation equipment and military-grade electronics.

FR4 PCBs have quickly become the go-to choice for electronic circuitry due to their versatility, reliability and cost-effectiveness. Their composition includes electrical insulation properties, thermal stability and mechanical strength making them suitable for a range of industries and applications. By understanding FR4’s characteristics and advantages electronics designers and enthusiasts can make informed decisions to create efficient yet robust boards for their projects.

FAQ:

- What is FR4 Printed Circuit Board?

FR4 (Fire-Retardant 4) PCB refers to a grade of material used in the manufacture of printed circuit boards (PCBs.) It’s a composite made of woven fiberglass cloth and flame-retardant epoxy resin, offering high mechanical strength, good insulation properties, and excellent resistance to moisture and thermal stress. - Why is FR4 a common material for PCBs?

FR4 Printed Circuit Board’s popularity resides in its cost-effectiveness and comparatively easy manufacturing process. Also, its properties such as a stable dielectric constant, low water absorption, good rigidity, and good thermal resistance make it appropriate for a variety of typical electronic applications. - What applications use FR4 Printed Circuit Boards?

FR4 is the standard material for many types of electronic devices and general-purpose PCBs. Potential applications range from home electronics to complex high-frequency technology – power electronics, automotive, LED lighting, and more. - Are there multi-layer FR4 Printed Circuit Boards?

Yes, multi-layer FR4 Printed Circuit Boards are standard in the electronics industry. These consist of multiple layers of FR4 material laminated together, with copper tracks etched on each layer to form the electrical circuits. - What is the typical thickness of an FR4 Printed Circuit Board?

The standard thickness of an FR4 Printed Circuit Board is 1.6mm. However, thickness can vary based on the specific application requirements, ranging from as thin as 0.2mm to as thick as 3.2mm. - What are the temperature limits for FR4 Printed Circuit Boards?

FR4 material can typically handle continuous operating temperatures up to about 130°C. However, it’s important to keep in mind that the actual temperature rating of a specific FR4 Printed Circuit Board will also be influenced by the type and density of the components mounted on it. - How does the FR4 Printed Circuit Board perform in RF applications?

FR4 can be used for Radio Frequency (RF) applications, but it’s not the best high-frequency material due to its higher dielectric constant and loss tangent. High-frequency applications usually employ specialized RF materials to ensure signal integrity. - How is FR4 compared to other PCB materials?

FR4 often competes with other materials like polyimide or ceramics. These materials may offer better performance in terms of high temperature or high-frequency operation, but they also come at a higher cost, making FR4 a preferred choice for general-purpose applications. - Are there environmentally friendly alternatives to FR4?

While FR4 is the industry standard, there are ongoing efforts to find more environmentally friendly alternatives. For instance, materials such as paper/phenolic composites or composites using natural fibers are being explored. - What does the Surface Mount Technology (SMT) process look like for FR4 Printed Circuit Boards?

FR4 is commonly used in SMT, where components are mounted directly onto the surface of the PCB. The PCB is prepared by applying solder paste to the appropriate pads, placing components using a pick and place machine, and then reflow soldering in an oven to secure the components to the PCB.