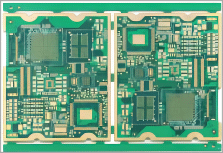

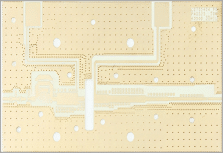

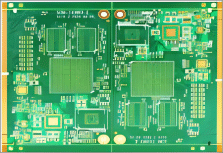

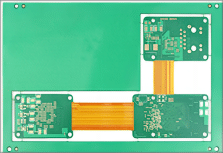

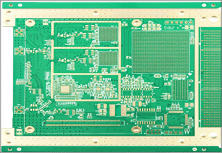

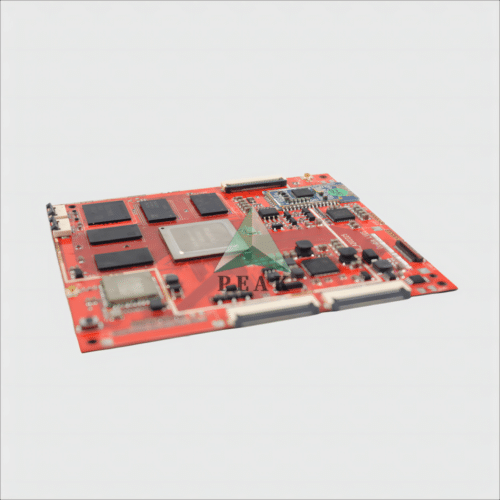

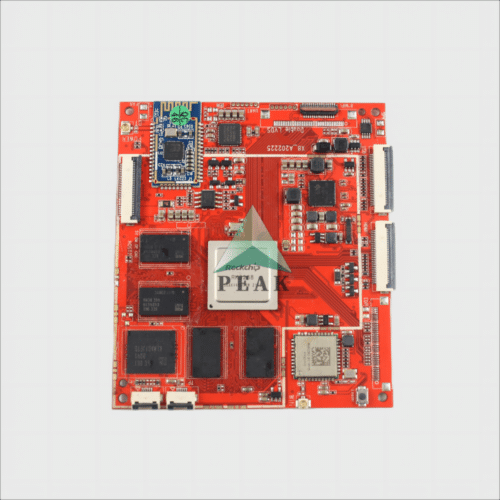

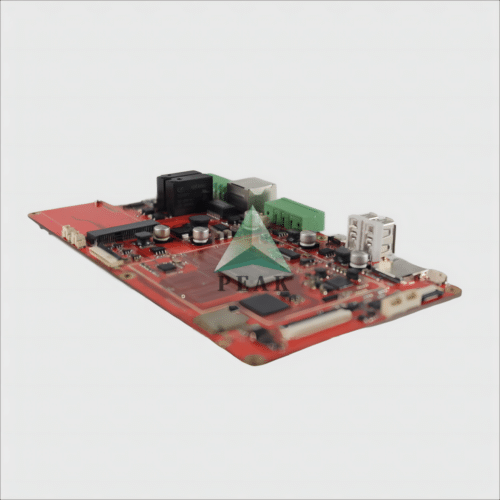

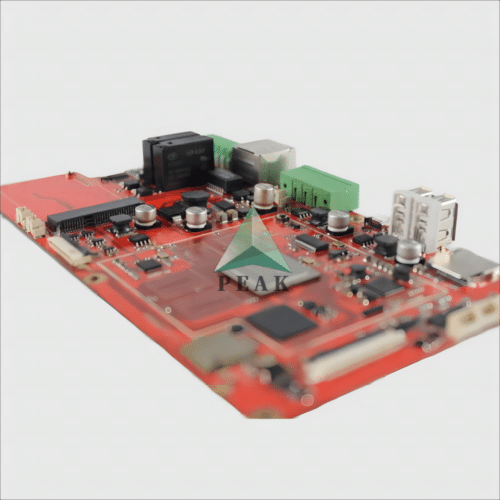

Exploring FR4 PCBs – The Versatile and Reliable Choice for Electronic Circuitry

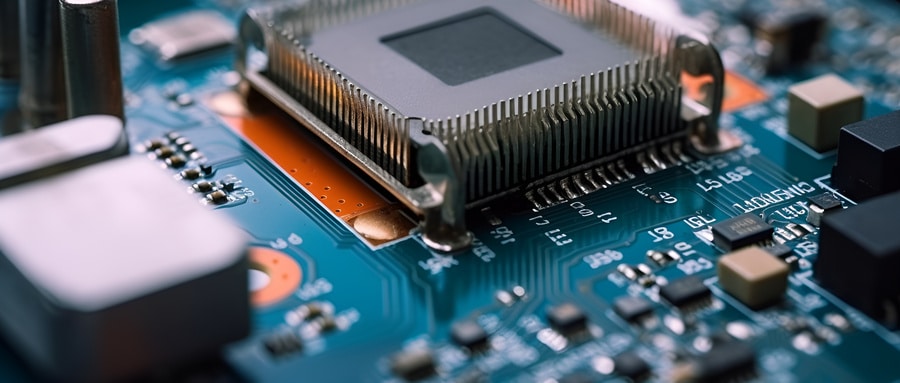

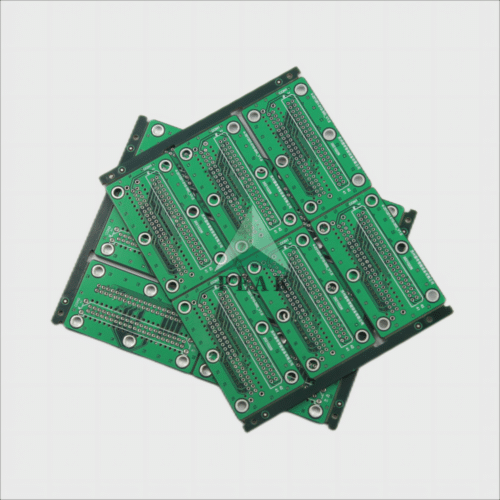

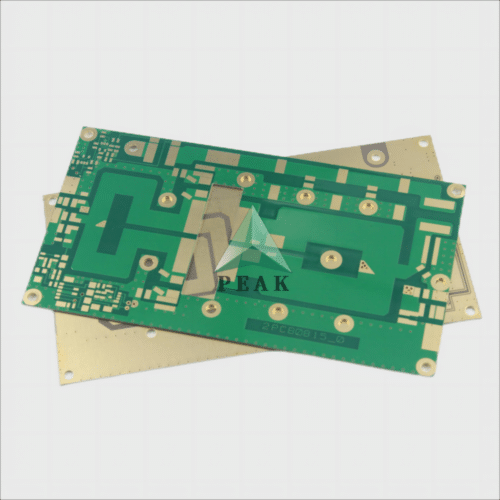

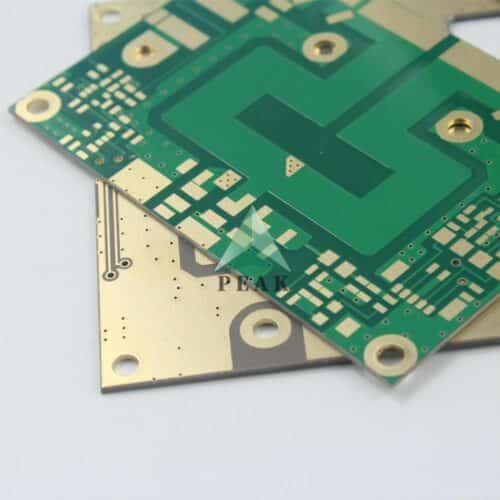

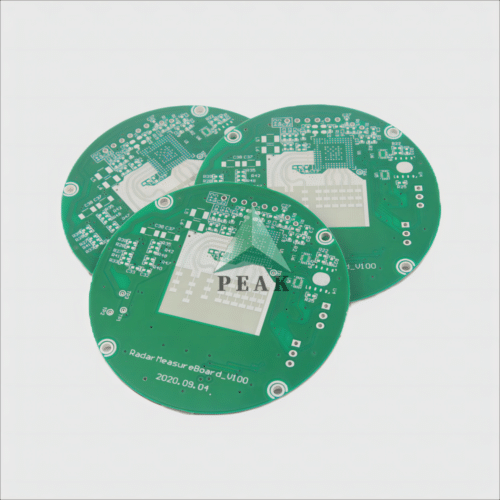

Exploring FR4 PCBs – The Versatile and Reliable Choice for Electronic Circuitry When discussing electronic circuit boards, the term FR4 often comes up. This substrate material is commonly used for manufacturing printed circuit boards (PCBs). We will explore this world of FR4 PCBs here by exploring their composition, properties, advantages and applications – so you […]