Mastering the Intricacies of PCB Certification: An Essential Guide for 2023

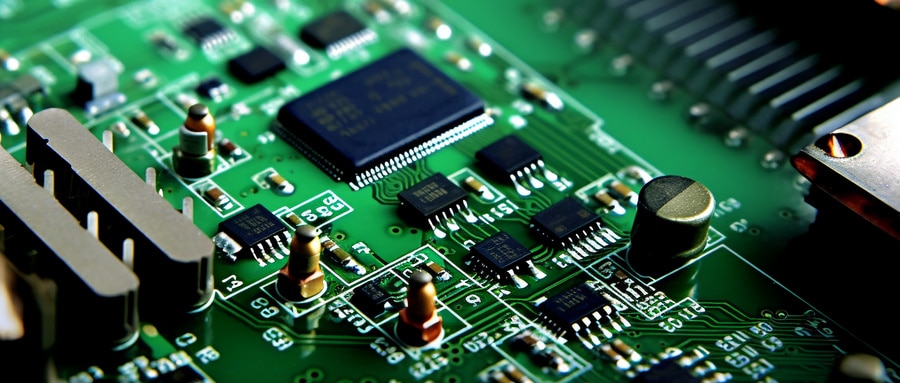

Introduction: The Printed Circuit Board (PCB) industry represents an exquisite marriage between technology and engineering innovation. As our reliance on electronic devices continues to increase, their significance has never been clearer. Therefore, in 2023 understanding how to obtain PCB certification has become of prime concern for manufacturers and engineers globally.

1. Understand Printed Circuit Board Certifications:

PCB certification is an integral component of compliance and quality assurance processes for PCB manufacturers, certifying their product to meet safety, quality, and performance standards set by organizations such as Underwriters Laboratories (UL), CE (European Conformity) or RoHS (Restriction of Hazardous Substances), among others.

2. Importance of PCB Certification:

Due to an increase in global standards and demand for safer, higher-quality products, PCB certification cannot be understated in its significance. As an assurance of quality and safety standards, certification helps establish credibility across domestic and global markets while opening up doors to greater business opportunities.

3. Path to Certification:

An application process to attain PCB certification can often be complex and involved. Acquiring it requires extensive knowledge of certification requirements, planning for rigorous tests, and maintaining accurate documentation.

4. Learn About Certifications:

a. Underwriter’s Laboratories Certification: Recognized for its stringent safety and quality standards, this certification stands out among others as being of particular value to manufacturers.

CE Marking: CE marking is a legally-binding certification which guarantees compliance with European health, safety and environmental protection standards for products sold within Europe.

RoHS Certification: An international standard that seeks to reduce or eliminate harmful substances in electrical and electronic products.

5. Best Practices for Acquiring PCB Certification:

Gaining certification can be challenging but is certainly achievable. A careful approach, preparation, testing, documentation and regular training on compliance with current norms are necessary elements. Furthermore, system upgrades should also be part of this consideration.

6. Key Obstacles and Solutions:

Acquiring PCB certification is no simple task; challenges will inevitably arise. These may include understanding and complying with current norms, time and financial restrictions as well as possible roadblocks to compliance. There are solutions available from hiring professionals to train employees through certified vendors or suppliers.

7. Case Studies: Examining Success Stories:

True insights come from real-world narratives, so here we explore some successful case studies of companies who navigated around challenges to earn PCB certification.

Conclusion:

As we head towards 2023, the circuit board industry’s complexity continues to unveil itself. Navigating through PCB certification’s maze represents an integral step on a manufacturer’s and engineer’s journey towards end user trust and eventual business expansion.

Let’s join forces and explore the complex world of PCB certification – an integral component in today’s electronic society!

FAQ:

- What is a PCB certificate?

A PCB certificate refers to a certification awarded by a recognized authority, attesting that a printed circuit board (PCB) has met certain predefined standards. - Why is a PCB certificate important?

It’s important because it validates that the PCB complies with internationally recognized standards. It ensures quality and reliability of the PCB. - Which standards are commonly referred to in a PCB certificate?

PCBs often conform to IPC standards, such as IPC-A-600 for PCB acceptance, and IPC-6011 for generic performance specification. - Who are the typical issuers of PCB certificates?

Recognized standard organizations like IPC, UL (Underwriters Laboratories), RoHS (Restriction of Hazardous Substances) are some of the entities. - Does a PCB certificate warrant that the PCB is properly functioning?

No, a PCB certificate typically verifies the board’s design and construction meet certain standards. It doesn’t guarantee the board’s functionality. - What is the process for attaining a PCB certificate?

Typically, the PCB needs to be submitted to the issuing authority for testing and inspection based on the specified standards. - What is a UL-certified PCB?

A UL-certified PCB is one that has been tested and certified by Underwriters Laboratories, an entity that assesses products for safety. - What is a RoHS-compliant PCB?

A RoHS-compliant PCB is one that adheres to the Restriction of Hazardous Substances. It means that it doesn’t contain certain harmful chemicals in its manufacture. - Are PCB certificates internationally recognized?

Yes, certificates like IPC and UL are internationally recognized. - Do I need a PCB certificate to manufacture PCBs?

While not always required, having a PCB certificate can give your customers an assurance of your product’s quality and safety. It can also be mandated in certain jurisdictions or industries.