An In-depth Analysis into the World of Bare PCB Board: Understanding Their Significance

Electronics encompass a vast world, yet at its heart lies one component whose significance cannot be overstated: Bare PCB Board. This article will help you navigate their complexity to better comprehend their significance, operation and indispensable role within electronics.

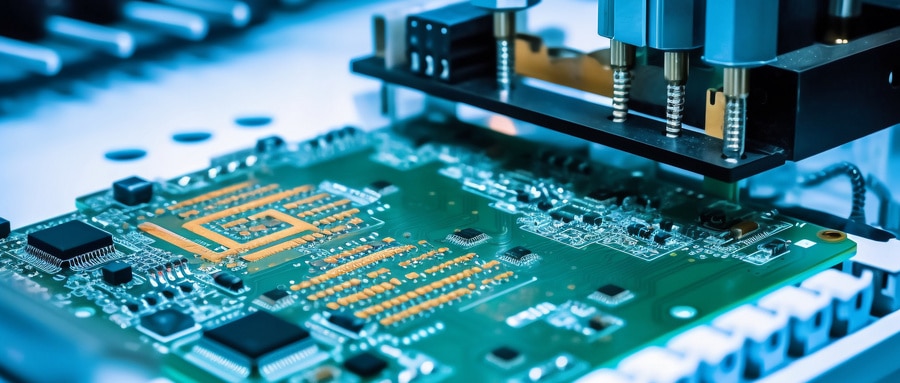

At first, it is necessary to define what a Bare PCB Board truly entails. PCB stands for “Printed Circuit Board”, and refers to an assembly of layers made up of insulation materials connected by electrical wiring traces that form its core. Nearly every electronic device you encounter contains such an assembly within it, from smartphones and space rockets all the way up to electronic musical instruments that use these sophisticated boards at their core in facilitating complex functions and interactions every millisecond.

Bare PCBs refers to boards devoid of components like resistors, capacitors or integrated circuits; this state-of-the-art platform acts as the silent stage upon which electronics orchestration takes place. A bare PCB serves as the canvas upon which an artist paints their masterpiece – without it, electronics would remain lifeless.

To understand the significance of PCB boards in electronics manufacturing, it’s necessary to explore their basic characteristics and identify their key components. PCBs include four layers:

- Substrate: The substrate material, usually fiberglass, provides rigidity and solidity that supports PCB’s physical structure.

- Copper: Adhering to the substrate is a thin layer of copper foil, which is then etched away during manufacturing to form pathways or tracks and allow current to pass through it.

- Soldermask: This protective layer shields copper layers from external exposure and prevents shorting out due to accidental contact with other metallic elements.

- Silkscreen: Silkscreened PCBs feature symbols, numbers and letters on their top layer to facilitate identification and assembly of electronics components.

Now you may be asking why PCB boards are important? Their significance stems from their unbeatable combination of simplicity and versatility – an unrivalled combination! A bare PCB board serves as the platform for designing an infinite variety of electronic devices as well as acting as the crucial connector between different electronic components that enable communication and synchronization between each component.

Prototyping in electronics involves prototyping with bare PCB boards as the central feature, providing engineers the means to test circuits, finalize layouts, and experiment with designs before moving forward to final assembly and production – saving both time and resources while efficiently eliminating potential issues.

To conclude, PCB boards serve as the silent pillars that support the universe of electronics. Their presence can be heard every time an electronic device sings its tune; yet remain an invisible but essential component in our rapidly technological world. Their quiet but essential presence exemplifies human ingenuity and aptitude by showing how a seemingly simple board can orchestrate complex tasks, innovations, and advancements.

Without PCB boards, electronics would cease to exist as we know them today. Their existence might seem underrated but their significance cannot be underestimated; their untold story of making our world more connected, smarter, and superior goes largely unacknowleged yet has an incredible impact. Next time you marvel an electronic device remember the unsung hero: PCB Boards that silently contribute a melody throughout digital society.

As technology evolves, the bare PCB board will continue to adapt and take on new forms and properties to keep pace with an ever-evolving electronic ecosystem. Already today, technologies such as rigid-flex PCBs, High Density Interconnect (HDI) PCBs, and IC-embedded PCBs show the adaptability inherent to their design and functioning – proof positive that PCB boards provide creative adaptability when designed and constructed correctly.

Miniaturized electronics components and wearable devices have seen increasing demand and rising trends such as IoT (Internet of Things), AI (Artificial Intelligence), AR (Augmented Reality), and VR (Virtual Reality). This pushes bare PCB design towards more compact, high-speed, and high-capacity variants; with innovations like graphene and carbon nanotubes on the horizon, their future looks bright for shaping electronics and digital applications in future years.

As society strives for eco-friendly alternatives in every industry, eco-friendly manufacturing practices will become ever more vital. Accordingly, “green” PCBs manufactured using recyclable materials free from hazardous chemicals will likely gain prominence and contribute to both a sustainable environment and electronic industry growth simultaneously.

Conclusion The world of bare PCB boards is an extraordinary realm full of hidden marvels and unexploited potential that plays a pivotal role in shaping the electronics industry. Their significance extends far beyond simply providing foundations for electronics devices; rather, it serves as an enabler of technology, innovation, and sustainable future initiatives. Every success story begins with one.

No matter what technological frontiers we encounter, one thing remains certain: The Bare PCB Board will remain an unsung hero who quietly propels us toward an incredible future full of limitless possibilities and unprecedented advancements. Here’s to celebrating their history, understanding their present, and anticipating their future; always remembering that behind every technological breakthrough lies an unsung hero known simply as The Bare PCB Board!

Undoubtedly, we owe much to these unsung heroes of technological development; their story deserves to be heard and celebrated. So let us embark on this adventure into the unknown, delving deeper into technology because behind every elaborately decorated surface lies something exquisite yet simple – The Bare PCB Board.

Bare PCB Board FAQ:

- What is a Bare PCB Board?

A Bare PCB Board is a printed circuit board without any electronic components, used to mechanically support and electronically connect electronic devices. - How is a Bare PCB board made?

This process involves various steps like designing a board layout, applying a layer of copper, and etching to create a circuit. - What materials are typically used in a Bare PCB Board?

The most common material used is FR4, a type of fiberglass. Copper is also used for the conductive layers. - What is a multilayer Bare PCB Board?

A multilayer Bare PCB Board consists of multiple layers of circuitry, which are laminated together to create a single board. - What is a Single-sided and Double-sided Bare PCB Board?

A single-sided PCB has components on one side of the board, while a double-sided PCB has components on both sides. - How are the components added to a Bare PCB Board?

Components are soldered onto the board using a process called SMT (Surface Mount Technology) or through-hole technology. - What is the cost of producing a Bare PCB Board?

The cost of producing a Bare PCB Board varies depending on the design, materials used, number of layers, and complexity of the circuit. - How are Bare PCB Boards tested?

There are various methods to test a Bare PCB Board, including visual inspection, automated optical inspection (AOI), and electrical tests. - What are the common problems with Bare PCB Boards?

Some common problems include poor soldering, incorrect component placement, and issues with the design of the board. - Where can I get a Bare PCB Board manufactured?

There are numerous manufacturers who offer PCB manufacturing services. It’s recommended to compare prices, review quality, and consider turnaround time before choosing a service.