Navigating the Intricacies: How to Test PCB Board?

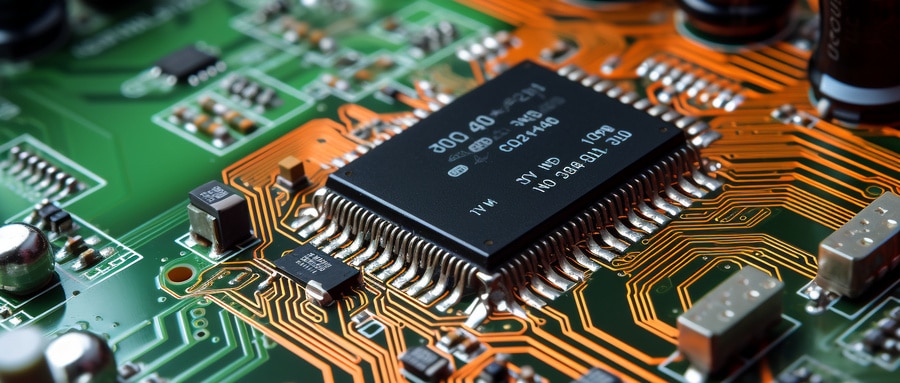

Electronic device development involves designing and testing of printed circuit boards (PCBs). A PCB serves as the backbone for every electronic gadget, regulating functionality and performance. Therefore, PCB testing is an integral aspect of quality control in electronic manufacturing – this article presents a step-by-step guide on how to thoroughly assess one.

Before getting started with PCB testing, it is imperative that we understand its purpose. PCB testing seeks to detect any potential performance flaws during early production stages, serving as an invaluable quality control measure that ensures our final product functions properly while mitigating risks associated with future performance issues.

Let’s dive deep into the meticulous yet fascinating process of testing PCB boards effectively.

1. How to Test PCB Board? Visual Inspection:

Visual inspection is the cornerstone of PCB testing. With its plain-sight inspection method, this stage can easily spot conspicuous faults such as missing components, incorrect parts and improper positioning. Tech such as Automatic Optical Inspection (AOI) may prove invaluable for larger production runs as it scans quickly and precisely through HD cameras to inspect each PCB thoroughly.

2. How to Test PCB Board? Power-Up Test:

The power-up test serves as the second phase of PCB testing and requires powering up the board in order to inspect for shorts on its PCB surface.

3. How to Test PCB Board? Analog Signature Analysis (ASA):

Additionally referred to as power-off testing, Analog Signature Analysis (ASA) uses a sinusoidal waveform to inspect each component at its nodes in an effort to detect defective parts on your circuit board even without power being available – thus potentially avoiding additional damage caused by powering-up testing.

4. How to Test PCB Board? In-Circuit Test (ICT):

An ICT employs a bed of nails tester to assess each component on a PCB for its functional performance and detect open circuits, short circuits, incorrect components being incorrectly installed and even correct polarity issues.

5. How to Test PCB Board? Functional Test:

This stage of PCB testing serves to verify its overall functionality by simulating real working conditions.

Remind yourself that expeditious and thorough PCB testing can save time, reduce costs and ensure a quality final product. Don’t underestimate or underrate its significance; even the best designs may fail if their implementation is shoddy. Use this step-by-step guide as your go-to manual on testing a PCB board to make your electronics manufacturing journey smooth sailing!

Now that the foundations have been laid, future articles will delve deeper into specific elements of PCB testing, including advanced techniques and technological innovations within industry.

Note: Please take all precautions necessary when handling electronic components to avoid injury or damage to yourself or property. Always referring to manufacturer guidelines prior to handling electrical devices or components is highly advised.

Founded in 2007, PEAK Co.,Ltd is an electronic solutions company offering 1-64 layers PCB fabrication, assembly, testing & validation of rigid, rigid-flex, HDI, high frequency, high speed, metal core, IC substrate, substrate-like and other special PCB. Our modern 54,000 square foot manufacturing facility allows us to provide all rigid & rigid-flex services under one roof and offer quick-turn capabilities. PEAK has a professional reputation for developing high-performance solutions for technically advanced OEM’s in a variety of markets including aerospace and defense, medical, computer, communication, server, semiconductor IC, automotives, industrial control, optoelectronics, LED and others.

FAQ:

- What is PCB testing?

- Why is PCB testing necessary?

- What tools are required to test a PCB board?

- What is the process to perform a PCB test?

- What are the different types of PCB testing methods?

- How does an In-Circuit Test (ICT) work for PCBs?

- How does a Flying Probe Test work in PCB testing?

- What are the common defects that can be identified through PCB testing?

- What is functional testing in PCBs?

- How can I perform manual visual inspection of a PCB?

- What are the common problems that occur in PCB testing?

- What is the importance of Automated Optical Inspection (AOI) in PCB testing?

- What steps can I take if my PCB fails the test?

- Is there a standard to follow for PCB testing?

- How does testing increase the reliability of a PCB?