Understanding PCB Prepreg: Properties, Benefits, and Applications

PCB Prepreg: Introduction and Overview

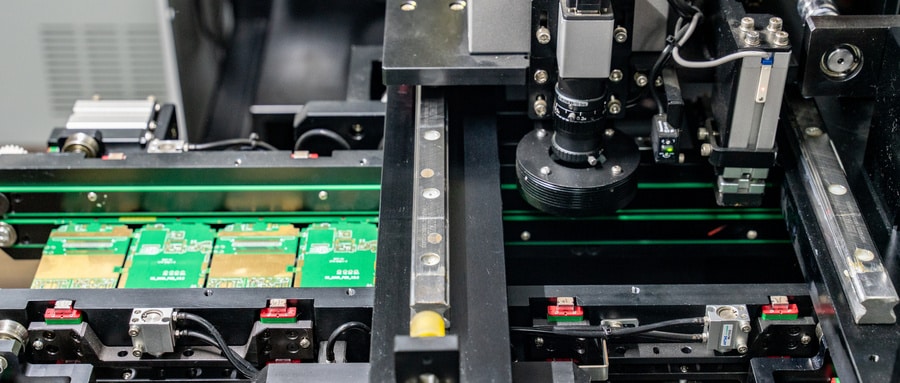

PCB prepreg, short for “pre-impregnated,” is an integral component in the production of printed circuit boards (PCBs). It plays an essential role in protecting structural integrity and reliability of electronic devices. Here, we explore its properties, benefits and applications within the electronics industry.

What Is PCB Prepreg?

PCB prepreg is a composite material composed of fiberglass cloth impregnated with resin, typically epoxy. This layer acts as an insulating barrier between copper layers on a PCB and contributes to both mechanical and electrical performance, thus adding strength and reliability. Prepreg is typically sandwiched between copper layers during manufacturing to form a strong and durable structure.

Properties of PCB Prepreg

- Dielectric Constant and Dissipation Factor of PCB Prepregs

Its mes mes mes PCB prepregs have exceptional dielectric properties that preserve their integrity across various frequencies, while their dielectric constant and dissipation factor have significant bearing on both signal integrity and performance of PCB boards. - Thermal Stability: PCB prepregs provide exceptional thermal stability, guaranteeing their circuit board’s integrity even under high-temperature conditions. Their thermal resistance also allows it to withstand temperature variations during soldering processes without compromise to its structural integrity.

- Mechanical Strength: PCB prepregs increase rigidity and mechanical strength for increased overall reliability, providing structural support while also preventing warping or flexing during operations or handling.

- Electrical Insulation: PCB prepreg’s primary purpose is to provide electrical insulation between copper layers. This effectively prevents short circuits and interference by isolating conductive traces and components on the board from each other, effectively eliminating short circuits and interference issues.

Advantages of PCB Prepreg Material

- Increased Design Flexibility: PCB prepregs provide greater design freedom due to their compatibility with various stacking configurations and thickness options, giving designers greater design freedom in creating multilayer boards tailored specifically for individual performance requirements.

- Improved Signal Integrity: PCB prepreg is known for its superior dielectric properties that prevent signal loss and distortion, providing higher speed/frequency signal integrity in applications like telecom and high-end electronics. These properties ensure data transmission with precision at higher speeds/ frequencies without distortions in transmission rates or distortion levels. This feature makes PCB prepreg an indispensable solution.

- Improved Thermal Management: PCB prepregs with high thermal conductivity provide efficient heat dissipation, providing better temperature-sensitive component management in demanding environments and thus increasing stability and longevity of electronic devices.

- Cost-Effective Solution: Incorporating PCB prepreg into manufacturing can result in cost savings, thanks to its excellent mechanical strength which reduces reinforcement materials needed, simplifying production processes and cutting overall manufacturing costs.

Applications of PCB Prepreg

PCB prepregs find various uses in various industries, including:

- Consumer Electronics: From smartphones and tablets to home appliances and wearable devices, printed circuit board prepregs play an indispensable role in producing electronic devices for daily use.

- Automotive Industry: printed circuit board prepregs are widely utilized in automotive electronics, powering essential features like infotainment systems, advanced driver assistance systems (ADAS) and engine management systems.

- Aerospace and Defense: Aerospace and defense industries heavily rely on printed circuit board prepregs for creating highly reliable circuit boards used in avionics, communication systems, weapons guidance systems.

- Industrial Automation: Printed circuit board prepregs play an indispensable role in industrial automation applications, providing precise control systems, motor drives and sensing devices that facilitate efficient operations.

- Renewable Energy: Printed circuit board prepregs play an indispensable role in renewable energy industries like solar power and wind turbine systems, providing efficient energy conversion and reliable transmission.

Printed circuit board prepreg is an integral component in producing high-quality printed circuit boards. Boasting properties like dielectric stability, mechanical strength and thermal resistance that contribute to overall reliability and performance of electronic devices, knowing its significance across different industries helps optimize design choices while guaranteeing successful production of advanced electronic systems.

FAQ:

- What is a printed circuit board prepreg?

A printed circuit board prepreg is a pre-impregnated material used in multilayer printed circuit boards (PCB) for bonding together the core materials. It is fiberglass impregnated with a thermoset resin material that hardens (or “cures”) under heat and pressure. - What’s the role of a prepreg in PCB manufacturing?

Prepreg forms an essential part of multilayer PCBs. It acts as an adhesive and insulating layer between the copper clad laminates (CCL) layers or cores in a multilayer PCB and provides electrical insulation and bonding strength. - What does the term ‘prepreg’ stand for?

The term ‘prepreg’ stands for ‘pre-impregnated’. It refers to the infusion of a resin system in a sheet of material under controlled temperature and pressure. - How is prepreg used in the PCB production process?

During PCB fabrication, layers of prepreg are laid together with copper foil or partially etched copper-clad laminate, then the stack is subjected to heat and pressure. The heat causes the prepreg resin to melt and flow, and the pressure ensures that layers bond together to form a single compact circuit board. - What types of resins are used in prepreg?

Epoxy resins are commonly used in manufacturing prepregs due to their good mechanical properties, cost-effectiveness, and electrical performance. - Does the thickness of prepreg matter in PCB design?

Yes, the thickness of prepreg plays a significant role in PCB design. It can affect the overall board thickness, electrical properties and the reliability of the final product. - What is B-stage prepreg?

B-stage prepreg refers to the stage in the curing process where the material has been partially cured or hardened. This makes it a semi-solid that will not melt but can soften and flow under heat and pressure. - How is the prepreg thickness measured?

Prepreg thickness is usually measured in Mil (1 Mil = 0.001 inch) or Microns. It relates to the weight of the prepreg resin and the type of fiberglass weave. - What is the shelf life of prepreg materials?

The shelf life of prepreg depends on storage conditions, specifically temperature. Under refrigeration (5C or below), the shelf life can be approximately 6 months. However, once removed from refrigeration, it should be used typically within a few days. - Can prepregs be made from materials other than fiberglass?

While fiberglass is the most common material, prepregs can also be made from materials like polyimide and Teflon for high-performance applications. The choice of material depends on the intended use and requirements of the final PCB product.