Diving Into the Core: What is Prepreg in PCB?

What is prepreg in pcb? That’s an interesting question.

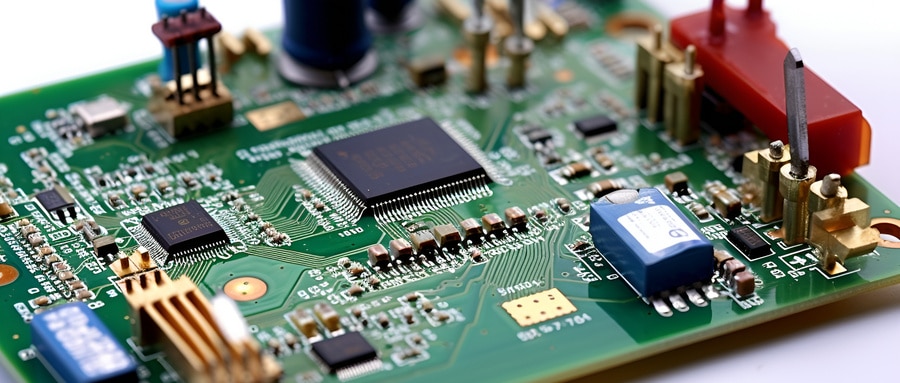

Print circuit board (PCB) production requires numerous unsung heroes whose contributions often go unseen. Prepreg is one such unsung hero in PCB production that helps bind layers together for maximum PCB performance.

Prepreg, or Pre-impregnated Composite Fibers, are raw fibreglass sheets infused with epoxy resin that remain only partially hardened after production; this allows them to liquify and solidify upon lamination into boards’ various layers for an improved bond.

Thin sheets play an integral part in PCB manufacturing, contributing various properties that directly influence its performance, design, and overall functionality. But before delving deeper into its roles it is vital to understand its makeup as a material itself.

What is prepreg in pcb? Prepreg (pre-impregnated fibreglass) is a material soaked with resin during its manufacturing process, passing it through heated rollers system before beginning its curing process – but without reaching completion. This semi-solvent state allows it to flow and stick, ultimately hardening during final lamination stage – hence its name, prepreg, or pre-impregnated material.

An integral purpose of prepreg is acting as the adhesive between multiple layers on a PCB before and after lamination, providing strength to hold them together during and after lamination. This role becomes particularly crucial with multilayer PCBs where functionality and density require multiple circuitry layers to be tightly packed together for compact assembly.

What is prepreg in pcb? Prepregs also play a key role in shaping the electrical properties of PCBs. Their composition – composed of epoxy resin and fibreglass, in particular – plays an influential role in shaping dielectric constant values – this value determines how quickly signals travel across a board; lower dielectric constant values mean faster signal transmission times.

Prepregs play an essential role in shaping PCBs’ thickness in terms of design implication; their layers determine its final thickness, making this an essential design consideration. Ensuring appropriate thickness for any application ensures structural integrity, robustness, and compatibility.

Prepreg selection also plays a pivotal role in heat resistance and thermal reliability of PCBs, helping improve their heat dissipation capabilities and thus their performance in high temperature applications.

Industrial applications of prepreg follow industry standards; their specific use can vary depending upon individual project requirements such as layers on a PCB, circuit design complexity, thermal requirements or functional specifications that dictate which prepregs should be chosen or applied for use.

Prepreg sheets in PCB materials must not be treated lightly or taken for granted; they fulfill several essential roles that help hold layers together, influence electrical properties, determine thickness and improve heat resistance. PCB manufacturers must consider these aspects carefully when choosing which number and type of prepreg sheets will make up their designs.

Prepreg is an indispensable yet underrated component in PCB manufacturing. Its elegant blend of adaptability and functionality further illustrates its worth while emphasizing its essential role in marrying performance with durability and resilience in PCB designs.

What is prepreg in pcb? I believe this article has been answered. Understanding prepreg is one of the keys to developing a greater comprehension of PCB construction, design and performance dynamics. Gaining this insight not only sheds light on production processes but also on tangible mechanisms defining an operational capability and constraints of every PCB in production – not only its surface components but also the unseen linchpin known as prepreg which keeps everything together beneath it all.

FAQ:

-

What is prepreg in PCB?

-

How is prepreg used in PCBs?

-

What is the importance of prepreg in multilayer PCBs?

-

What types of prepreg are commonly used in PCB fabrication?

-

How does prepreg impact the overall performance and reliability of a PCB?

-

Can prepreg thickness be varied in different parts of a PCB?

-

What are the safety measures to be taken when handling prepreg material?

-

How is prepreg’s quality assessed in the PCB production process?

-

What factors affect the shelf life of prepreg material?

-

Can prepreg influence the signal quality in a PCB?

-

What happens to prepreg during the lamination process in PCB production?

-

How does the temperature affect prepreg during the PCB production process?

-

How is prepreg stored before use in PCB fabrication?

-

What are the environmental considerations when disposing of prepreg material?

-

What industry standards apply to the use of prepreg in PCB manufacturing?