Unmasking the Secret of Efficient and Safe: How to Clean Flux off PCB?

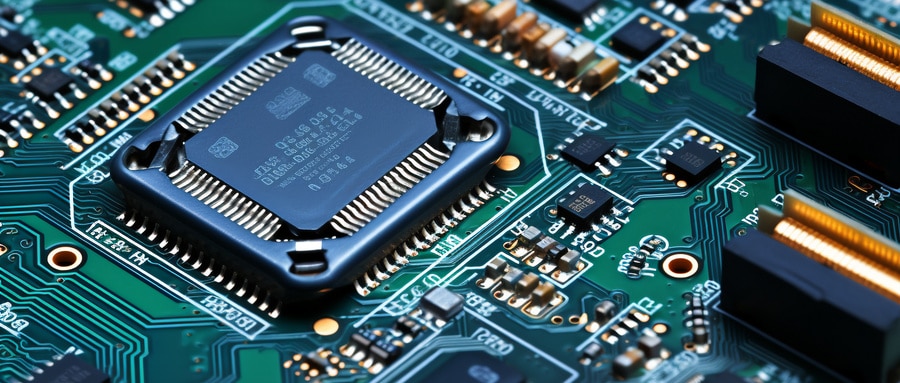

Printed Circuit Boards (PCBs) are an integral component of most electronic devices today, and soldering is one of their assembly processes that cannot be overlooked. Unfortunately, soldering creates flux residue that must be cleared off the PCB after soldering has taken place; an efficient and safe cleaning procedure could extend its longevity and improve its operation; this article offers guidance and expert advice on how to accomplish that process effectively and safely.

How to Clean Flux off PCB? Understanding Flux for Soldering

Flux is an integral component of soldering, helping create a firm and reliable bond between solder and metal surfaces. While flux may play an integral part in this process, any remaining residue often adheres to PCBs after soldering has completed, potentially contributing to corrosion, electrical leaks or component failure down the line.

How to Clean Flux off PCB? Prepping for The Cleaning Challenge

Before embarking on any cleaning venture, it is essential that you arm yourself with the appropriate tools:

Isopropyl alcohol (IPA) is an excellent solvent for dissolving flux residue, while soft bristle brushes are suitable for gently scrubbing residue without damaging PCBs. Canned or compressed air is then used to dry off PCBs after cleaning has taken place and Nitrile gloves and goggles provide personal protective gear for safety measures.

How to Clean Flux off PCB? Flux Removal: Step by Step Guide

- Prepare: De-energize and remove the PCB from the device while wearing protective eyewear and nitrile gloves for safety.

- Flux Inspection: Conduct a visual examination of your PCB for visible flux residue, typically appearing as a brown, shiny film on its surface.

- Applying Isopropyl Alcohol: Apply a generous amount of isopropyl alcohol directly over areas containing flux residue to begin dissolving it immediately. The alcohol will start dissolving it within seconds!

- Brushing Off Flux: With the soft bristle brush, carefully scrub any areas where IPA was applied. Be gentle as to not damage any of the PCB components.

- Rinsing: After scrubbing, rinse the board with IPA to wash away the flux particles that have been dislodged by scrubbing – using a syringe or squeeze bottle will aid this process.

- Drying: Once the PCB has been thoroughly rinsed, it is time to dry it with canned or compressed air. Carefully direct air onto stubborn areas where liquid may pool; ensure all areas of liquid have been extracted before reinstalling your board.

- Check for Flux Residues: With a magnifying glass in hand, inspect the PCB to make sure all flux residues have been eliminated; otherwise repeat step 7.

How to Clean Flux off PCB? Final Thoughts

Flux removal from PCBs is essential to the long-term performance and efficiency of your device, and with the appropriate tools and techniques it becomes an effortless task. The protocol in this guide ensures adverse effects associated with accidental flux contamination are avoided to protect equipment lifecycle and performance.

Understanding flux residue’s threats, selecting suitable personal protective gear, and properly performing PCB Flux cleaning have all been covered here to master its art while assuring both efficiency and safety – turning once daunting PCB maintenance into an effortless experience.

Continuous learning and keeping up-to-date with industry practices are vital in maintaining and improving PCBs longevity and operation. So keep an open mind, engage your mind, and embark on this never-ending learning experience!

FAQ:

- What is flux in relation to PCBs?

- Why is it important to clean flux off a PCB?

- What happens if flux is not cleaned off a PCB?

- What materials do I need to clean flux off a PCB?

- What is the safest method to remove flux from a PCB?

- Can I use isopropyl alcohol to clean flux off my PCB?

- What is the step-by-step process of cleaning flux from my PCB?

- Are there any precautions I need to take while cleaning flux off a PCB?

- How often should I clean my PCB from flux?

- Can I damage my PCB by cleaning it too hard?

- Can I use distilled water to clean flux off the PCB?

- Are there professional PCB cleaning solutions available?

- How do I dry my PCB after cleaning the flux off?

- Is it necessary to remove flux for fully working circuits as well?

- How to prevent the accumulation of flux on PCBs in the first place?