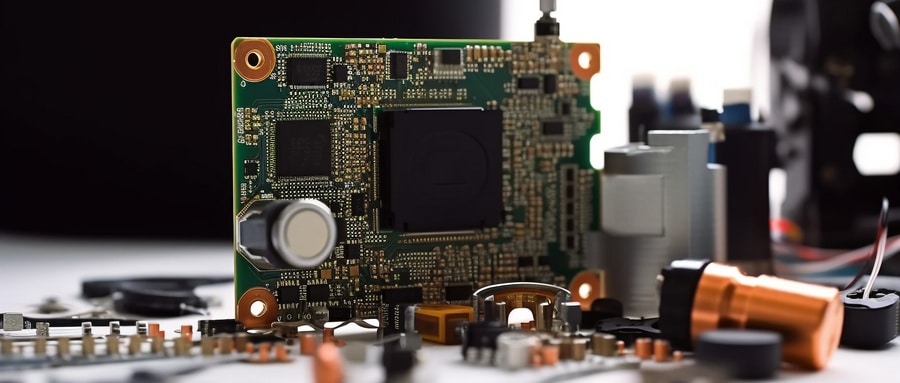

Mastering High Frequency PCB Design: A Comprehensive Guide in the Digital Age

Due to increasing demands for faster, more energy-efficient electronics, High-Frequency PCB design has quickly become one of the premier fields in electronic engineering. This comprehensive guide offers an in-depth exploration of this branch of engineering while uncovering its complexities and providing methods for mastering its unique challenges.

Understanding High Frequency PCB Design

High-Frequency PCBs have become an indispensable feature in modern electronics, enabling high-speed data, wide bandwidth and superior performance. A High-Frequency PCB typically refers to PCBs operating above 1 GHz; they’re often found in radar systems, radio wave receivers and high-speed data transmission devices; their popularity should increase even further with 5G’s arrival.

Understanding how to design High-Frequency PCBs has become a critical skill for electronic engineers. While designing these boards may seem simple, there can be numerous complexities involved – issues such as signal loss, impedance control and transmission lines must all be carefully considered when designing such circuits.

Mastering the Design Process

As we progress through the design process, it cannot be overemphasized the significance of beginning with an effective pre-layout phase. A well-thought out pre-layout serves as the cornerstone of project success and designers should pay special attention to signal integrity, isolation, and return paths during this initial stage of pre-design.

At this stage, it is critical that designers focus on reducing signal loss. Designers must account for high-frequency signals which tend to “ride” on the surface of conductors and cause surface wave propagation; known as the skin effect. Proper material selection and copper thickness can significantly lower losses associated with signal propagation.

Selecting Appropriate Materials for Construction

Material selection is another integral aspect of designing a High-Frequency PCB. Dielectric constant (DK), an important property which affects signal speed and impedance – the lower its DK value, the faster signal speed will be. Common materials used include cost-effective FR4 grade glass-reinforced epoxy laminate as well as polytetrafluoroethylene (PTFE), which has an exceptionally low Dk value.

PCB Stack-Up Plays an Essential Role

Carefully planning PCB stack-up can provide both enhanced signal integrity and reduced radiation. For example, placing ground and power planes adjacently reduces loop inductance; using multiple ground planes increases shielding effect to lower electromagnetic emissions.

How to Overcome Signal Integrity Challenges

Signal integrity can be one of the biggest challenges in High-Frequency PCB design, with issues like cross-talk, noise generation and signal loss potentially undermining its performance. Ground segregation techniques along with effective routing strategies and differential signaling may help address such signal integrity challenges.

Understanding PCB Manufacturing

After completion of design, manufacturing will commence. For maximum effectiveness and reduced errors/rework, it is vital that PCB manufacturers are involved early in the design process to ensure an easy transition from design to production and avoid delays and unexpected costs.

Succinctly, mastering High-Frequency PCB design involves grasping many concepts ranging from signal integrity and material selection to PCB stack-up and PCB design stack-up. By keeping the key points highlighted here in mind, electronic engineers can more efficiently and effectively design robust High-Frequency PCBs capable of keeping up with today’s fast-paced digital era.

FAQ:

- Q: What is a high frequency PCB?

A: High frequency PCBs are designed to perform at frequencies of 500MHz to 2GHz, used in applications like radio frequency, microwave, and digital signal processing circuits. - Q: What materials are used for high frequency PCBs?

A: Special materials that minimize signal loss, such as PTFE (Teflon), FR-4 grade material, or Rogers material, are used for high frequency applications. - Q: Are high frequency PCBs more expensive to manufacture?

A: Yes, they tend to be more expensive due to the special materials, more careful production process, and additional quality assurance required. - Q: What industries commonly use high frequency PCBs?

A: They are commonly used in telecommunications, aerospace, medical equipment, radars, broadcasting, and other environments demanding high performance. - Q: How is signal integrity maintained in a high frequency PCB?

A: It’s maintained through careful design to minimize signal loss and cross talk, using measures such as controlled impedance, careful routing, and shielding. - Q: Do high frequency PCBs require special design software?

A: While basic PCB design software can handle high frequency PCB design, specialized software can accommodate the unique challenges of such designs, helping to maintain signal integrity and avoid performance issues. - Q: Is it more difficult to design high frequency PCBs?

A: Yes, as these designs require extra attention. Factors such as material selection, trace width, trace spacing, and board thickness have a significant effect on the board’s performance. - Q: What are the key parameters to consider while designing a high frequency PCB?

A: Keys parameters include dielectric constant of the material, signal speed, signal integrity, impedance control, loss tangent, and thermal properties. - Q: How to handle thermal management in high frequency PCB?

A: This can be done by using materials that have good thermal conductivity properties, taking measures to disperse heat, and reducing hot spots. - Q: Are there any specific quality checks for high frequency PCBs?

A: Yes, specific checks may include verifying that the correct material has been used, the desired impedance has been achieved, and the board’s performance at the intended frequency, among others.