Demystifying RF PCB Designs: Navigating Complex Challenges Through Simplified Steps

Appealing to Protagonists: RF PCBs Are at the Core of Modern Tech

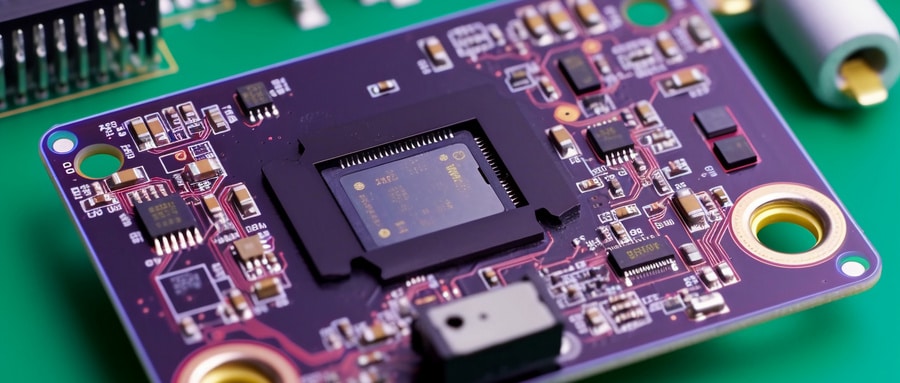

Radio Frequency Printed Circuit Boards (RF PCBs), one of the cornerstone technologies that enabled us to reach 2023’s wireless age, could not exist without these foundational components of technology: Radio Frequency Printed Circuit Boards. These advanced, complex devices have dramatically altered our interactions with digital realms like telecom and beyond.

Building the Basis: Outlining RF PCBs

Let’s begin by exploring what an RF PCB is. In essence, an RF PCB is a special type of printed circuit board designed to transmit and receive signals in the Radio Frequency (RF) range – typically 3kHz to 300GHz; however its scope of applications and design complexity goes much further than this.

RF PCBs: Then and Now

It would be fascinating to explore how the design of RF PCBs has progressed throughout history. A variety of factors has led to these advancements – ranging from increased data speeds to stronger signal strengths, longer range, and overall system efficiency.

Navigating RF PCB Design: Understanding Its Complications

Though RF PCB design shares similar elements with traditional PCB design, the process presents unique challenges. How do intricate mechanisms manage the intricacies inherent to radio frequency signals? We will address these obstacles throughout this article: from material selection, trace widths and via structures through signal integrity considerations and more.

Components of an RF PCB: Material Selection

Materials used in RF PCBs have an enormous effect on their performance, so selecting suitable substrates and dielectric constants becomes a crucial element of success. We will explore this aspect, exploring criteria for material selection as well as their implications on performance.

Trace Talk: Key Considerations in Setting Up PCB Lines

Design of an RF PCB board involves considering line considerations – or paths connecting elements in an electronic circuit. In this section we will address their role, how to minimize losses along these paths, and maximize efficient space utilization.

VIAS’ Role in RF PCB Manufacturing

Vias are essential elements in the design and manufacturing of RF PCBs; they provide electrical connections between different layers. Selecting appropriate vias is key to crafting efficient and optimized designs for these boards.

Manage Skin Effect and Dielectric Losses

Radio frequency propagation through printed circuit boards (PCBs) may lead to issues like skin effect and dielectric losses that severely compromise signal integrity. Learn how to best manage and mitigate such effects to ensure optimal RF PCB performance.

Striving towards optimal design: Complying with EMC/EMI regulations

Maintaining electromagnetic interference and adhering to regulatory compliance are both integral parts of RF PCB design. We will offer insights into how designers navigate these obstacles to ensure seamless operation and compatibility of components within an electromagnetically diverse environment.

Unleash the Power of Simulation Tools

As we move into the digital era, embracing modern simulation tools is vitally important. This section addresses how these tools can assist with verifying and optimizing RF PCB designs to provide improved reliability and performance.

Construction of the Future: New RF PCB Innovations on the Horizon

At last, we explore future trends and envision where RF PCB designs might go in the near future. Join us as we predict technological developments and innovations that could expand this field further.

As we explore RF PCB designs together, the aim is to ensure that this journey is informative and valuable, leaving you with a profound knowledge of this essential technology for modern wireless communication.

No matter if you are just getting into RF PCB design or are a veteran who wishes to stay up-to-date, this comprehensive guide promises to meet all of your needs. Don’t leave anything important behind on the journey; buckle up!

FAQ:

- Q: What is an RF printed circuit board?

A: An RF (Radio Frequency) printed circuit board is a type of PCB that operates on signals at microwave frequencies (1 GHz and above). They are used in high-frequency applications like Wi-Fi, antennas, and RF receivers. - Q: What materials are normally used in RF printed circuit boards?

A: The materials used in RF printed circuit boards can include FR4-grade glass laminate but often use more advanced materials such as polyphenylene oxide (PPO) or PTFE composite resins because of their stable electrical properties at high frequencies. - Q: How are RF printed circuit boards different from standard PCBs?

A: RF printed circuit boards are designed to minimize signal loss and cross-talk due to the high-frequency signals they carry. They often require special material considerations and more precise manufacturing processes. - Q: What are the common applications of RF Printed circuit boards?

A: They are commonly used in applications that involve signal transmission over the air, such as telecommunications, satellite technology, radar systems, and other high-frequency products. - Q: What factors affect the performance of an RF printed circuit board?

A: Factors can include circuit layout, signal integrity, impedance control, material selection, and heat dissipation capabilities. - Q: What is impedance control in RF printed circuit boards?

A: Impedance control involves designing the PCB to maintain a specific impedance level across the board to ensure signal integrity, particularly vital in high-frequency RF designs. - Q: Why is heat management important in RF printed circuit boards?

A: High-frequency operations can generate significant amounts of heat. Proper heat management ensures the board and components don’t fail due to overheating. - Q: How can I ensure the best design for my RF printed circuit board?

A: Close collaboration with a knowledgeable manufacturer, understanding of your specific application, and following best practices like proper layout and material selection can all contribute to the design of a high-performing RF printed circuit board. - Q: Are RF printed circuit boards more expensive to manufacture?

A: Generally, yes. Because they often require specialized materials and more advanced manufacturing processes, RF printed circuit boards can be more costly than regular printed circuit boards. - Q: Can I use any PCB manufacturer to create my RF printed circuit board?

A: No, RF printed circuit board manufacturing requires special expertise and capabilities. Make sure your chosen PCB manufacturer has experience with RF printed circuit boards and can meet your specific requirements.