Unveiling the Advantages and Applications of Aluminium PCBs

Electronic industry demands are constantly driving innovation and progress within PCB (printed circuit board) design, pushing manufacturers towards products capable of higher performance, reliability and durability. At the forefront of these advances is aluminium PCBs’ rise as modern electronic designs take advantage of their unique properties to design for greater performance, reliability and longevity. Understanding why aluminium PCBs have such an essential place is important – what advantages they bring and where they typically are applied are key factors in this regard.

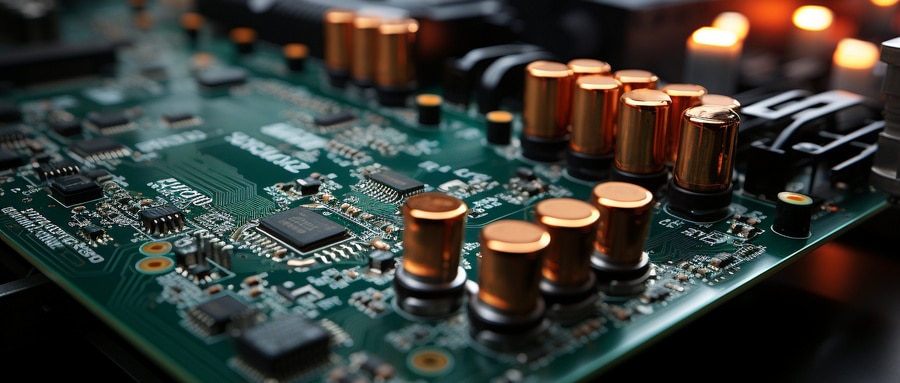

Aluminium PCBs (also referred to as metal-backed PCBs) are a type of PCB constructed on a metal backing with thin dielectric layers bonded onto them that serve to provide thermal conductivity, electrical insulatiory material, rigidity, durability and heat dissipation – ideal for high power/high temperature operations.

Are the key advantages of aluminium PCBs that set them apart from other forms of PCBs?

1. Improved Heat Dissipation:

Aluminium PCBs stand out as being especially adept at dissipating heat. Aluminium allows boards to divert it away from essential components, reducing risk of overheating while aiding efficient functioning of complex electronic configurations. This feature makes aluminium PCBs suitable for applications where components generate lots of heat or in high-stress environments where heat build-up may occur.

2. Increased Durability:

Aluminium is known for its strength and resilience, qualities it passes down into PCBs made with it. Aluminium-based PCBs boast long lifespans compared to their counterparts – making them perfect for critical applications that demand reliability over long periods.

3. Cost-Efficient:

Aluminium PCBs offer advanced capabilities while remaining cost-efficient, as they feature longer service lives with lower maintenance and repair expenses – making them an economical choice for many manufacturers.

4. Environmental-Friendly:

Aluminium PCBs also score points when it comes to sustainability; aluminium is non-toxic and recyclable, making these PCBs a more eco-friendly choice.

Aluminium PCBs offer many benefits that make them appealing in various applications, most prominently LED lighting systems due to their heat dissipation qualities. High frequency devices such as RF and microwave circuits frequently utilize aluminium PCBs due to its thermal conductivity and electrical insulation properties; aluminum PCBs can also be found used extensively in automotive power converters, motor controllers and LED lights; home appliances, audio equipment and power supplies also benefit from using aluminium PCBs extensively.

Aluminium PCBs represent an exceptional combination of thermal management, durability, cost-effectiveness and environmental sustainability that make them ideal for today’s high-stress, high-performance applications – making them a top choice among designers and manufacturers alike.

As an electronics professional or enthusiast, understanding aluminium PCBs’ potential provides you with an expanded toolbox that can unlock the full scope of your designs. Harnessing their power means we are moving closer towards more reliable, cost-effective, and environmentally-friendly electronics – from illuminating rooms with LED lamps to driving electric cars – aluminium PCBs are part of the journey and deserve recognition as unsung heroes in our world of electronics! Here’s to aluminium PCBs as unifying forces within electronics!

FAQ:

- What is an Aluminium Printed Circuit Board?

An aluminium printed circuit board is a type of printed circuit board that uses a metal base, typically aluminium, for improved heat dissipation. They are also referred to as metal-core printed circuit boards (MCPCBs) and are commonly used in applications with high heat generation. - How does an Aluminium printed circuit board work?

The aluminium in the PCB serves as a heat sink, allowing for effective heat transfer from the components on the board. This keeps the components cooler, enhancing performance and increasing the lifespan of the product. - What are the advantages of using an Aluminium Printed Circuit Board?

Compared to standard fiberglass PCBs, aluminium printed circuit boards lower operating temperatures, improve heat dissipation, increase product lifespan and are generally more durable. They are also light in weight, cost-effective, and environmentally friendly. - What are the applications of an Aluminium Printed Circuit Board?

Aluminium Printed Circuit Boards are often used in LED lighting applications, power supplies, automotive systems, and high-frequency circuitry, among other high-heat applications. - Are Aluminium Printed Circuit Boards more expensive?

Despite their many advantages, aluminium Printed Circuit Boards are typically more affordable than ceramic PCBs but can be more expensive than standard FR4 PCBs, mainly due to the additional thermal benefits that they offer. - How is the manufacturing process different for Aluminium Printed Circuit Board?

Aluminium Printed Circuit Boards use a special manufacturing process that includes isolating the copper circuitry from the aluminium backing using a thermally conductive dielectric layer. This process can differ from manufacturer to manufacturer. - Are Aluminium Printed Circuit Boards heavier due to their metal base?

Although metal is generally heavy, aluminium is one of the lighter metals and often lighter than some alternative materials. This helps reduce the overall weight of the final product. - What types of components can be used with Aluminium Printed Circuit Boards?

Any component that can be used with a standard PCB can be used with an aluminium Printed Circuit Board. The main consideration is the heat generation of the component, as the enhanced heat dissipation of aluminium PCBs is one of their main advantages. - Can Aluminium PCBs be multi-layered?

Yes, while single layer designs are the most common due to aluminium’s thermal properties, multi-layer aluminium PCBs can also be manufactured for more complex circuit designs. - What is the level of thermal conductivity in Aluminium PCBs?

The level of thermal conductivity in aluminium PCBs typically ranges from 1.0 to 2.2 W/m-K, depending on the specifics of the dielectric material used. This is an aspect to be considered during the design process as it directly influences the PCB’s performance and longevity.