The Ultimate Guide to PCB Laminate: Navigating the Heart of Your Electronics Design

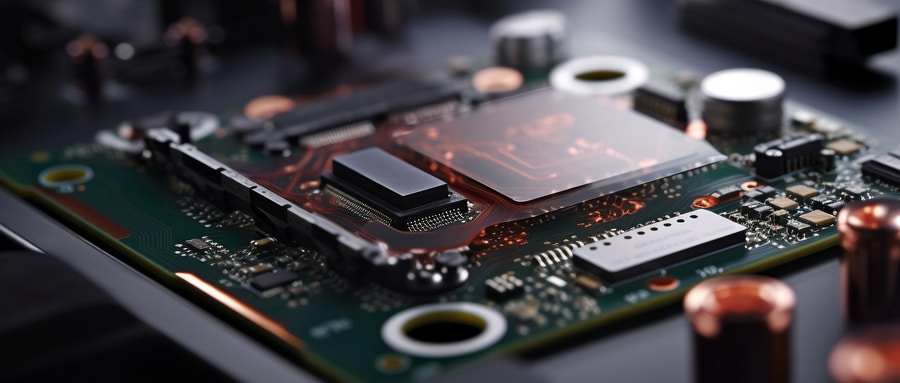

Electronics is not solely about circuits and their components – there’s also the Printed Circuit Board (PCB) laminate to consider!

PCB Laminates form the backbone of electronic assemblies, acting as the substrate material that holds together everything from resistors to integrated circuits. Today we will embark on an educational journey exploring this seemingly simple yet intricate foundation in electronics.

1. What Is PCB Laminate?

An ideal circuit board laminate consists of heat-resistant plastic layered with copper. They’re composite materials composed of fibreglass (FR4) as the substrate material and an epoxy resin as a bonding material – with copper layers providing crucial foundation for circuit etching.

2. Types of PCB Laminates

Users have many choices available to them when it comes to laminates for various applications and thermal requirements, from standard FR-4 laminates all the way through high frequency ceramic-filled laminates.

3. Importance of PCB Laminates

circuit board laminates do more than provide a foundation for your circuit; they also offer essential electrical insulation and mechanical support, contribute to assembly processes, thermal management strategies and ultimately impact device performance.

4. How are PCB Laminates Produced?

An inside look into the sophisticated process of circuit board laminate production, from treating, layering, laminating, cooling and finishing.

5. Applying PCB Laminates

From consumer electronics to military grade equipment, an entire array of industries rely heavily on different kinds of circuit board laminates.

6. Selecting the Appropriate PCB Laminate

Tips and considerations to assist in making an informed decision when selecting the circuit board laminate that best meets design requirements, environmental conditions and project budget constraints.

7. Future Trends and Advancements in PCB Laminates

Discover how circuit board laminates continue to change rapidly in an ever-evolving world. Be up-to-date on the cutting-edge innovations and future trends shaping this field of technology.

By the end of this comprehensive guide, you will have gained invaluable insights and a firm grasp of circuit board laminates. No matter whether you are just getting into electronic design or are an experienced PCB assembly practitioner, this book serves to expand your understanding, inform choices, and optimize PCB design processes – ultimately the heart of electronics design is key for creating successful and efficient circuits!

Remember, every successful electronic assembly begins with carefully selecting and understanding circuit board laminates. So let’s embark on your journey towards becoming expert circuit board laminate designers! Happy designing!

FAQ:

- Q: What is a PCB Laminate?

A: PCB Laminate is a material, usually composed of epoxy resin and woven glass fiber, that is used to make the core and insulating layers of a printed circuit board. - Q: What are the common types of PCB Laminates?

A: Common types include FR-4, high frequency (RF/Microwave), Polyimide, PTFE, BT-Epoxy, CEM-1, and CEM-3. - Q: How is a PCB laminate chosen?

A: Choice depends on several factors, including desired electrical properties, stability, cost, and the specific application of the PCB. - Q: How does PCB Laminate impact PCB performance?

A: The laminate can impact the PCB’s electrical properties, thermal management, and structural rigidity. Its properties guide signal integrity, speed, and overall functionality of the PCB. - Q: Can one modify a PCB laminate after it has been formed?

A: Modifications after formation are typically not possible, as the laminate material has been set and is hard to alter without damaging the board. - Q: What is the most commonly used PCB laminate?

A: The most commonly used type is FR-4 laminate due to its good electrical and thermal characteristics, as well as its cost effectiveness. - Q: How are circuit board laminates categorized?

A: PCB laminates are categorized by their resin type, reinforcement type, Tg (glass transition temperature), dielectric constant, and other technical aspects. - Q: What is the purpose of Tg in circuit board Laminates?

A: The Tg or glass transition temperature is the temperature at which the laminate material changes from a rigid state to a flexible or softer state. It’s a key characteristic to consider in high-temperature applications. - Q: Does the thickness of the laminate layer affect the performance of the PCB?

A: Yes, it can affect signal transmission, power handling capability, and the strength of the PCB. - Q: Are there environmentally friendly circuit board laminate options?

A: Yes, some manufacturers now provide “Green” laminate options made from environmentally friendly materials with less harmful production processes.