Mastering PCB Mount Techniques: An At-Depth Overview of Selection, Installation, and Best Practices

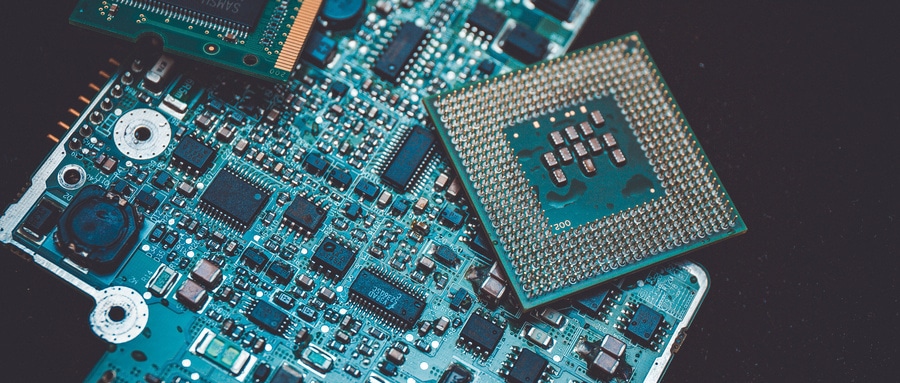

Assembling the printed circuit board (PCB) correctly in electronics projects is often as critical to its design as designing the circuit itself. While a circuit may function on paper or even breadboard, mounting it physically into an enclosure or product can be much trickier; PCB mounts ensure the board remains securely attached inside devices to enhance functionality and longevity; this article presents an in-depth view of PCB mount types, installation methods, and best practices for successful usage.

PCB mounts are fastening mechanisms designed to securely fasten printed circuit boards (PCBs) inside an enclosure and to provide insulation between electronic components and their housing for safety reasons, and to prevent static discharge and other potential damages from occuring.

There are various PCB mounts on the market, each offering specific applications and advantages.

- Spacers and Standoffs: These cylindrical fasteners are used to elevate PCBs from enclosures or surfaces, with threaded or unthreaded options available.

- Snap Lock PCB Supports: These supports securely affix PCBs without tools or external forces being needed.

- Adhesive Backed PCB Supports: These plastic mounts feature adhesive backings that make installation on most surfaces quick and simple.

- Edge Holding PCB Supports: These supports secure the edge of the board to prevent flex and potential component damage.

Installation processes depend on the type of mount involved; with threadless standoffs, all you need to do is slide them over mounting holes and snap them in place; threaded standoffs would require screws for securement while snap locking and adhesive mounts do not usually require tools during setup.

Selecting PCB mounts depends on factors like their weight and size, environmental conditions, and available space in an enclosure.

Best practices for mounting PCBs require following manufacturer instructions closely for installation and taking into account thermal conditions when placing the board. Furthermore, an effectively mounted PCB will facilitate easier maintenance while decreasing potential damages.

PCB mounts play an indispensable role in ensuring the stability, functionality, and longevity of electronic devices. By understanding their various types and best practices for installation and usage, one can significantly boost overall device performance.

No matter if you are an electronics hobbyist, aspiring engineer, or experienced professional; this guide’s comprehensive exploration of PCB mounts will offer greater clarity for better project results in electronics projects of all kinds.

PCB Mount FAQ:

- What is a printed circuit board mount?

Printed circuit board mount is a term used to describe components that are designed to be directly attached or fitted onto a printed circuit board. - What are some common types of printed circuit board mount techniques?

Surface Mount Technology (SMT) and Through-Hole Technology (THT) are two of the most common techniques. SMT places components directly onto the surface of the PCB, while THT involves passing leads through holes drilled in the PCB. - What are the advantages of surface mount technology (SMT)?

SMT is often favored over THT because it allows for higher component density and can be automated, leading to reduced manufacturing cost and faster production times. - What is a Printed Circuit Board Mount Transformer?

A printed circuit board mount transformer is a transformer designed to be mounted directly onto the surface of a PCB. These are widely used in a variety of applications, including power supplies and telecommunications equipment. - How do I install Printed Circuit Board mount components?

PCB mount components are typically soldered onto the board. The specific process can vary depending on whether it is a surface mount or through-hole component. - What are Printed Circuit Board Mount Potentiometers?

PCB Mount Potentiometers are variable resistors that are designed to be mounted directly onto the PCB. They are used for adjusting the characteristics of electronic circuits. - Are there design considerations specific to PCB mount components?

Definitely. Things like the layout of the board, the available space, the heat produced by components, and even the overall weight of the board can all impact what types of components are best suited for PCB mount. - What is a PCB Mount Fuse?

A PCB Mount Fuse is a protective device designed to be mounted onto a PCB. When the current in the circuit exceeds a specified limit, the fuse will interrupt the electrical flow to protect the rest of the circuit from damage. - Why use PCB mount components?

PCB mount components save space, enhance circuit reliability, and simplify the assembly process by using automated soldering techniques. - Can I replace or repair a PCB mount component?

Yes, faulty PCB mount components can often be de-soldered and replaced. However, care must be taken to avoid damaging the board. Specific tools and skills may be required for this task.