Exploring PCB Board Thickness Considerations: Finding the Right Thickness

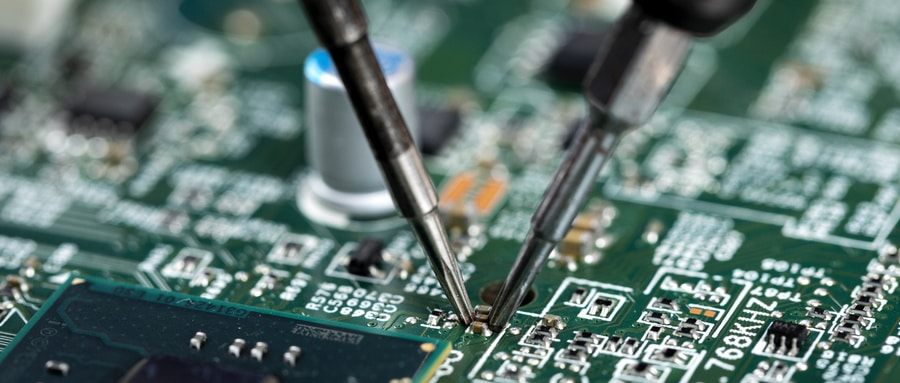

PCB board thickness is an integral component that can greatly influence performance, reliability and functionality of electronic designs. We will explore its significance, key considerations when choosing an ideal thickness, as well as its effects on various aspects of PCB design and manufacturing.

Importance of PCB Board Thickness for Effective Design Solutions

- Mechanical Robustness: The thickness of a PCB’s material has an impactful influence on its structural integrity and mechanical strength, so selecting one with appropriate thickness ensures it can withstand mechanical stresses like bending or twisting without jeopardizing its functionality.

- Flexibility: PCB board thickness has an effect on its flexibility or rigidity, depending on its intended use and application. Depending on its function – wearable devices with limited space constraints for instance or larger electronics with more structural needs might require flexible boards while others might need rigid ones for structural support purposes.

- Signal Integrity: PCB thickness has an impactful influence on signal transmission and impedance control, so taking note of it helps maintain consistent impedance for reliable high-speed signal integrity, while minimising reflections to ensure reliable data transfer.

- Thermal Considerations: PCB board thickness has an impactful impact on how heat generated by components is dissipated and dispersed across its surface area. Thicker boards offer better thermal conductivity by spreading and dispersing heat more effectively across their surface area.

Considerations When Selecting PCB Board Thickness

- Application and Space Considerations: When choosing PCB board thickness, keep both its intended use and available space in mind. Smaller devices might require thinner boards to fit into limited areas while more rigorous applications may need thicker boards for robustness.

- Mechanical Requirements of PCB: Examine the mechanical needs of your PCB, such as its load-bearing capacity or susceptibility to physical stress. Thicker boards provide greater rigidity and can withstand higher mechanical stresses.

- Component Mounting: When mounting components, consider their physical and thermal specifications – especially if surface mount technology (SMT) components or heavy ones are being used. Thicker boards provide better support for heavier or larger components.

- Signal Speed and Impedance Control: PCB thickness has an effect on signal integrity for high-frequency signals, especially those transmitted at higher speeds. Thinner boards offer controlled impedance for transmission at higher speeds with decreased losses or reflections as a result of transmission.

Considerations in Manufacturing Process Development

- Plating and Copper Thickness: Carefully consider your plating and copper thickness requirements when designing a PCB as they could impact manufacturing processes such as etching, plating and solder mask application.

- Assembly Process Compatibility: Make sure that the PCB thickness chosen matches with assembly processes such as component placement, soldering and reflow soldering. Thinner boards may prove more challenging during assembly.

- Fabrication Capabilities of PCB Manufacturers: Confirm that your chosen PCB manufacturer can fabricate boards of your desired thickness. Some may have restrictions regarding what thicknesses they can produce.

By considering factors like mechanical robustness, flexibility, signal integrity, thermal considerations and manufacturing processes you can determine the appropriate thickness for your specific PCB board application. Selecting an ideal thickness selection ensures reliability, performance and manufacturability for electronic designs.

FAQ:

- What is the standard thickness of a PCB board?

The standard thickness of a PCB board is 1.6mm. However, PCB thickness can vary, subject to the requirements of specific applications. - Can the thickness of a PCB board be customized?

Yes, the thickness of a PCB board can be customized to align with the need of specific electronic products or systems. - Are there any implications of a thicker or thinner PCB board?

The thickness of a PCB board affects its durability and rigidity. Thicker boards are more robust and less likely to break, while thinner boards offer more flexibility. Both have distinct use-cases in electronic systems. - What materials affect PCB board thickness?

Materials such as FR4 and copper, which are used for the base and conductive paths respectively, influence the overall thickness of a PCB board. - Is there any relationship between PCB board thickness and its working frequency?

Yes, the thickness of the PCB board affects its performance at different frequencies. Thicker boards typically perform better at lower frequencies. - How is PCB board thickness measured?

PCB board thickness is generally measured in millimeters (mm) or inches and is typically stated on the technical specifications provided by the manufacturer. - Does PCB board thickness affect its weight?

Yes, the thickness of a PCB board directly influences its weight. The thicker the board is, the heavier it would be. - Does the thickness of a PCB board influence its cost?

Generally yes, thicker PCB boards usually cost more due to the increased amount of material used. - Does the PCB board thickness change over time?

If properly maintained, the thickness of a PCB board should not change significantly over time. However, physical stress, high temperatures, or corrosive environments can potentially cause slight changes. - What’s the thinnest possible PCB?

Very thin PCBs do exist—the thinnest standard option in the industry is about 0.2mm, however, thinner options might be available based on specific manufacturer capabilities.