Defining and Exploring Standard PCB Panel Sizes: A Guide to Optimizing Your Design

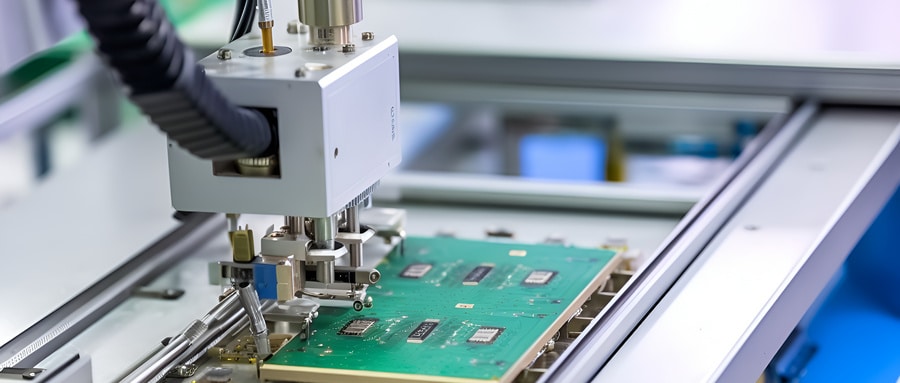

Circuit boards play an indispensable role in today’s tech-driven society that favors efficiency and consistency, PCBs (Printed Circuit Boards). Also referred to as printed circuit boards (PCBs), they act as nerve centers for numerous electronic devices. To fully comprehend PCBs we must first understand their significance – particularly its standard panel sizes which will assist in design optimization efforts. In this comprehensive guide we will delve deeply into standard PCB panel sizes and their significance on production processes.

Panel sizes are determined by manufacturers according to specific industry norms in order to maximize production efficiency, lower costs and minimize waste. A standard PCB panel size typically ranges between 18×24 inches or 457.2×610 mm; however other sizes may also be used depending on factors like fabricator preferences, equipment limitations and the nature of PCBs produced.

Why does PCB panel size matter? Simply put, its all about optimizing utilization and efficiency. Adherence to standard PCB panel sizes greatly simplifies production by enabling increased circuit boards to be produced on one panel at once, thus streamlining manufacturing, cutting costs, and minimizing waste.

Although 18x24inches (457.2×610 mm) remains a standard PCB panel size, other sizes exist that could also fit manufacturer needs and circuit board types; 21 x 24inchs(533.4 x 60inches 610 x 762mms are commonly seen depending on manufacturer requirements and board types – though 18×24 is often more convenient in meeting most configurations of equipment configurations seamlessly.

At a deeper design level, one must carefully consider the relationship between board layout and panel size. Knowing how best to lay out circuit boards on standard panel sizes can greatly increase efficiency while decreasing PCB fabrication costs in mass production stages.

Planning for panelization includes many elements – these can include break-away rails (commonly known as mouse bites), routing and scoring methods, space for handling/test points/fudicial marks/labels; all while fitting within the panel size. Careful consideration of these factors early can provide significant advantages during production/assembly processes later.

As we explore PCB panel sizes further, another crucial aspect is panel thickness. Common thicknesses for PCB panels range from 0.062 inches, 0.031 inches, 0.093 inches and 0.125 inches depending on your application; with 0.062 being considered the industry standard thickness.

At its core, understanding standard PCB panel sizes lies in accurately ascertaining your design and manufacturing needs. Doing this not only makes PCB designs more reliable but cuts costs and speeds time-to-market for products.

Navigating through the details and technicalities of standard PCB panel sizes may appear complex at first. But having a better grasp on this matter could prove instrumental in your electronic design optimization journey – just one piece of what drives our reliance on technology today.

Though PCB panel sizes follow an established norm, being flexible and understanding that every design may require its own approach is key to optimizing design processes, streamlining fabrication processes and reaching electronic design excellence. This comprehensive guide is meant to equip you with an in-depth knowledge of standard PCB panel sizes so you can optimize design processes, streamline fabrication and achieve electronic design excellence.

Standard PCB Panel Size FAQ:

- What is the Standard PCB Panel Size?

The standard PCB panel sizes vary depending on the manufacturer’s capabilities and the specifications of their machining and tooling equipment. However, a dominant standard in the PCB industry is 18 by 24 inches (457 mm by 610 mm). - Can I request a custom PCB Panel Size?

Yes, many PCB manufacturers can accommodate requests for custom panel sizes, although standard sizes are generally more economical and efficient. - Why do I need to consider the Panel Size constraints in PCB Design?

Considering panel size in the design phase can streamline manufacturing and reduce unnecessary costs. Keeping within the limits of standard panel size can aid in optimizing the number of PCBs on one panel, decreasing waste, and improving production efficiency. - Can the Panel Size affect the PCB Cost?

Yes, larger panels can accommodate more boards, often reducing the per-unit cost. However, larger or non-standard panels might require additional materials, tooling, or handling, potentially increasing costs. - What is Panelization in PCB Production?

Panelization is the process of grouping multiple PCB designs onto a single panel to maximize the utilization of the panel space. This can improve cost efficiency, enhance assembly speed, and minimize waste in PCB production. - How is the best Layout determined on a PCB Panel?

The most efficient layout depends on many factors, including the design of the PCB, the size and shape of the panel, and the processes used during assembly. It’s often a balance between maximizing usage of panel space and minimizing potential for damage or error during assembly. - How much Boarder space required in a PCB Panel?

A border of at least 3.175mm (0.125 inches) is generally required around the edge of the panel to accommodate handling and tooling during the manufacturing process. - Can any Shape or Size of PCB be accommodated on a Standard Panel?

While a variety of PCB sizes and shapes can fit onto standard panels, extremely large, small or irregularly shaped PCBs may present some challenges and limitations in terms of panel utilization and manufacturing process. - How does Standard PCB Panel Size affect the Turnaround Time?

Using standard panel sizes can often reduce production time because the manufacturer’s processes and tooling are typically optimized for these sizes. - What is the maximum PCB size that can be manufactured?

This entirely depends on the machinery and capabilities of the PCB manufacturer. However, most manufacturers can produce exceptionally large PCBs measuring up to 16″x22″ or more. It’s always best to consult with your PCB manufacturer regarding size restrictions and capabilities.