Cheap PCB Production: Your Ultimate Guide in Making the Best Budget Decisions

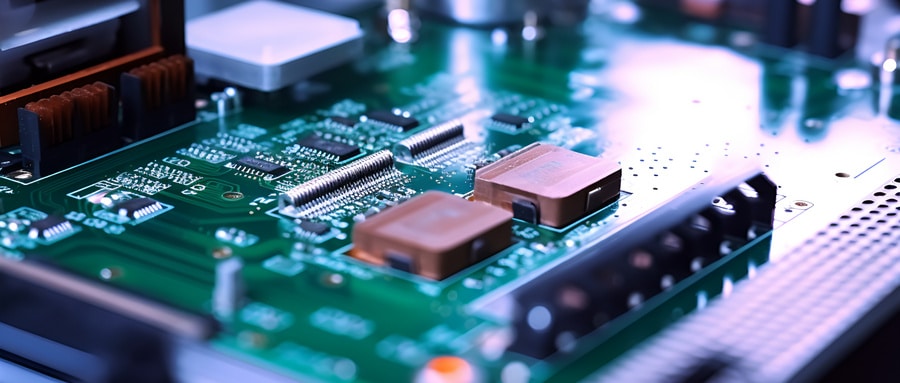

Technology continues to progress rapidly, creating an increasing need for affordable electronic components to keep up with new innovations. PCBs are one of the essential elements in modern electronics devices; yet cost effectiveness often plays a primary role for manufacturers, hobbyists, and innovators; thus leading us to seek cheaper PCB production methods while not compromising on quality as we search for affordability. You are about to discover just that as we dive into budget-friendly PCB production.

Chapter 1: Understanding PCB Fundamentals

Before exploring cost, it’s essential to understand what a PCB is and its significance within electronics. Simply put, a PCB is a thin board made of insulating material upon which conductive pathways (or traces) have been etched or printed – these serve to connect various electronic components mounted to it, providing a foundational platform for devices ranging from basic digital clocks to complex smartphones.

Chapter 2: Cost Dynamics of PCB Production

Now that we have covered the essentials, let’s investigate some of the major cost influencers for PCB production. A PCB’s cost can be affected by several factors including design complexity, layer count, material type, board size and volume ordered – these drivers must be understood and leveraged without impacting performance or value for your PCB purchase. To successfully locate cost-effective boards we must learn their importance while managing them effectively without sacrificing performance or functionality.

Chapter 3: Balancing Performance & Cost

Discovering a balance between cost and quality is of utmost importance as the most inexpensive PCB might not always meet your needs. Therefore, it’s essential that your supplier offers an effective quality assurance process; additionally they should provide all kinds of PCBs required by your particular application from simple single-layer boards to complex multi-layer ones. Strategies such as effective design, material selection and bulk purchases can all help maintain performance while simultaneously cutting costs.

Chapter 4: Sourcing for Cheap PCB Production Solutions

Though no single solution exists for finding an inexpensive PCB, this chapter provides strategies and resources that can assist in making wiser budgetary decisions. Pay attention to capabilities, certifications, customer service ratings and reviews when selecting suppliers – these will be important considerations in finding quality yet budget-conscious manufacturers.

Chapter 5: Trends in PCB Production at Affordable Cost

PCB manufacturing, like all industries, can benefit from modern technological innovations and advancements. From automation to environmental considerations of PCB production, future trends may alter cost dynamics of PCBs; staying informed about these potential changes will allow you to continue sourcing affordable options.

Here you have it – an exhaustive guide to cheap PCB production. Finding cost-effective options without compromising on quality can be found, and these pages hold all of the secrets needed for finding them! Happy reading and happy sourcing!

Be mindful that as you embark on this journey, recognizing cost dynamics, striking an appropriate balance between performance and cost, finding an affordable manufacturer, and keeping up with future trends are key components for ensuring affordable PCB production success.

FAQ:

- Q: What does “cheap PCB” refer to?

A: A “cheap PCB” usually refers to a PCB that is less expensive due to cost-effective manufacturing, reduced feature specifications, or bulk order discounts. - Q: Where can I find cheap PCBs?

A: Numerous online platforms and electronics manufacturers offer affordable PCBs. However, it’s important to research and choose a reliable supplier to ensure quality isn’t sacrificed. - Q: Are cheap PCBs of lesser quality?

A: Not necessarily. The cost of a PCB can significantly depend on factors like design complexity, material type, layer count and manufacturing speed. A cheap PCB can still meet necessary quality standards if designed and manufactured properly. - Q: Can cheap PCBs handle complex circuit designs?

A: Yes. However, greater complexity usually leads to a higher cost. Cost-effective solutions might limit the complexity of design features, such as the number of layers or precision details. - Q: How can I make sure my cheap PCB is reliable?

A: It’s essential to select a reputable manufacturer with a proven track record. Reading customer reviews and requesting a sample can also help ensure reliability. - Q: Does the number of PCBs ordered influence the price?

A: Yes. Ordering PCBs in bulk often leads to significant discounts. - Q: Can the PCB assembly service add to the cost?

A: Indeed. Assembly services, especially for more complex boards or components, can add to the total PCB cost. - Q: Are there any ways to reduce the PCB manufacturing cost?

A: Minimizing the layer count, using standard sizes and shapes, and reducing the complexity of the design are typical methods to lower manufacturing costs. - Q: Can cheap PCBs be used in commercial products?

A: Certainly. As long as the PCB meets the quality requirements and reliability standards of the product, it can be used regardless of its cost. - Q: Are low-cost PCB materials reliable?

A: This depends largely on the requirements of the project. Lower cost materials can be plenty reliable for certain applications, but for high-stress or specialized use cases, more expensive materials may be necessary.