Navigating the Ins and Outs: A Comprehensive Guide to Blank PCB Boards

Blank Printed Circuit Boards (PCBs), at the heart of so many devices we use every day, might seem like mysterious tech components. Yet understanding their structure, function, and significance to electronics development is essential to better design and development of hardware products. This guide not only sheds light on blank PCBs but also offers a comprehensive view into their role today’s technological environment.

Understanding PCBs:

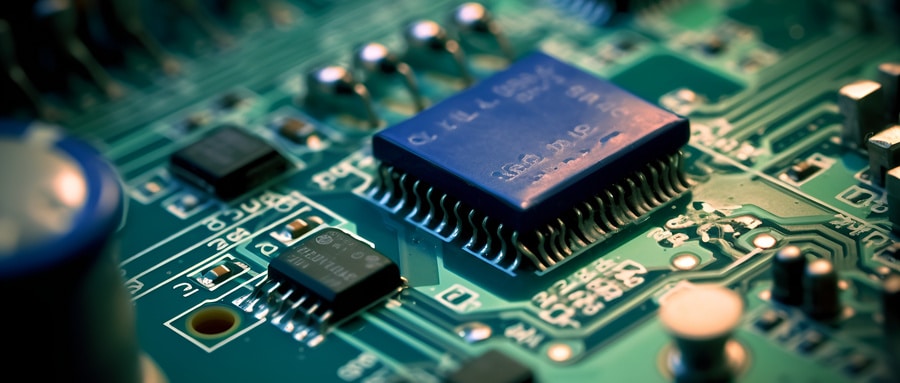

Every electronic device we encounter consists of an intricate web of interconnecting parts connected by wires and circuitry. This labyrinth resides on a printed circuit board (PCB), typically constructed out of fiberglass or composite epoxy material. Silicon chips known as integrated circuits (IC) along with capacitors, resistors and transistors are mounted on these boards in complex arrangements for efficient functionality.

Why Blank PCBs?

Blank PCB boards often form the first step of any project due to their customizability. With no predesigned circuits already laid out on them, blank boards provide developers with an open canvas on which to design the electronics necessary for their device or project – making these essential for both hardware developers and hobbyists.

Components of a PCB Board:

- Substrate: A fiberglass substratum provides rigidity and thickness to the board.

- Copper Layer: This thin copper foil press-fits onto a substrate where developers create circuit designs by etching through its pores.

- Solder Mask: The green insulation layer which protects copper tracks from short circuiting is called Solder Mask.

- Silkscreen: Silkscreen provides a final layer to guide accurate component placement.

Making of a PCB:

Producing a PCB involves several steps, such as layer alignment, laminating, etching and drilling and plating. High levels of precision and quality control are maintained at every step to deliver an ideal functional board at its completion.

Before buying blank PCB boards, take into account various aspects such as board type (rigid, flexible or flex-rigid), material thickness and layer count, technical specs like via hole size and trace thickness and copper weight requirements – remember, what works best will depend on both your project requirements and individual preference.

With rapid technological developments afoot, understanding building blocks like blank PCBs can deepen our appreciation of final products as well as help us become better consumers and possibly inventors ourselves. Therefore, whether you are an engineer, tech enthusiast, or simply curious reader gaining an appreciation of this unsung hero can only enrich your life!

Blank PCBs offer an intriguing world, and this article is just an introduction. As technology develops, so will blank PCBs; leading the way towards more sophisticated, reliable, and efficient electronic devices.

Blank PCB Boards FAQ:

- Q: What are blank PCB boards?

A: Blank PCB boards, also known as bare PCB boards, are boards without any components soldered onto them. They contain only the pattern of the circuit, with places marked for components to be soldered later. - Q: Where can I purchase blank PCB boards?

A: Blank PCBs can be purchased from various online retailers, electronic component stores, and through PCB manufacturers’ websites. - Q: What materials are used for blank PCB boards?

A: The most common material for blank PCB boards is Fiberglass Reinforced Epoxy Laminates (FR4). Alternative materials include Aluminum and Flexible Polymide depending on the desired properties of the board. - Q: Are blank PCBs available in different sizes and shapes?

A: Yes, blank PCB boards are available in a variety of sizes and shapes. The appropriate selection depends on the type of circuit to be assembled and specific requirements of the project. - Q: Can I design my own custom blank PCB board?

A: Yes, many manufacturers offer custom PCB services where you can submit your board design and they will manufacture them to your specifications. - Q: What is the cost of blank PCB boards?

A: The cost can vary significantly depending on factors such as board size, material, layer count, and quantity ordered. - Q: How can I tell the quality of a blank PCB board?

A: Quality can be assessed based on factors such as the board finish, precision of drilling, clarity of the silkscreen, and conformity to the original design dimensions. - Q: What methods can be used to make a blank PCB board at home?

A: Methods include etching (with substances like ferric chloride), CNC milling, or even laser cutting, although professional manufacturing is usually preferable for precise and multi-layered projects. - Q: What precautions should I take while handling blank PCB boards?

A: It’s important to avoid touching the copper areas of the PCB since oils from your skin can affect solderability. Anti-static precautions should be taken when handling them as well. - Q: Can blank PCB boards be multi-layered?

A: Yes, blank PCB boards can have multiple layers, ranging from a simple two-layer board to ones with many more layers for complex circuits.