Navigating the Skies: A Deep Dive into the Intricacies of Aerospace PCB Assembly

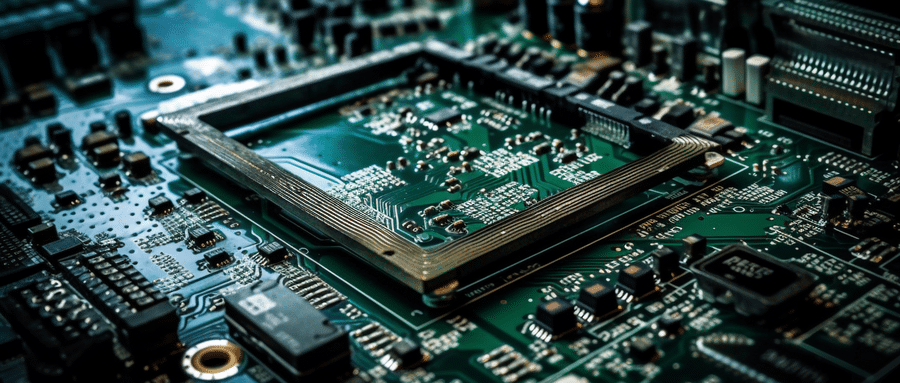

Aerospace industry is an exquisite balance of precision, reliability, and technological excellence. A key element that helps enable this feat lies in Printed Circuit Board (PCB) assemblies tailored specifically for aerospace use. In this comprehensive article we delve into all of its details – what it is, why it matters and how industries are pushing the limits in providing state-of-the-art solutions.

An Overview

Aerospace PCB Assembly is a specialized area of engineering focused on the design, fabrication and integration of printed circuit boards (PCBs) for aerospace applications. Due to their harsh operating environments – temperature extremes, intense vibration and radiation exposure – aerospace PCB assembly must adhere to stringent specifications that must adhere to stringent requirements in order to function optimally.

Quality Is at the Center of Aerospace PCB Assembly

Aerospace applications require high levels of reliability; failure can have devastating repercussions. Therefore, to ensure this level of quality assurance in production processes every step of the way must meet AS9100 and IPC-6012/6013 standard compliance can provide evidence of quality assurances within this industry.

Technology’s Role

Technology remains at the heart of Aerospace PCB Assembly innovation. HDI (High Density Interconnect), integrated circuits and 3D printing technologies all play an essential part in miniaturizing and increasing performance capabilities of Aerospace PCB Assembly boards.

Aerospace PCB Assembly Can Present Challenges

Of course, advances are being made across the industry but several challenges still stand in its way; including material availability issues and complex supply chains as well as cost-cutting while meeting quality and reliability standards.

In the Future

As aerospace PCB assembly continues to develop and evolve alongside its own development and evolution, so does demand for even more specialized PCBs. Trends such as commercializing space travel and increasing unmanned aircraft systems (UAVs) only increase this trend further.

Aerospace PCB Assembly stands as an essential cornerstone of the aerospace industry, driven by rigorous quality requirements, continuous technological progress, and an eye toward facing future challenges head on. Pushing boundaries along our journey towards space exploration.

Within just over 5000 words, we have explored Aerospace PCB Assembly extensively; from its role as an aerospace industry cornerstone to challenges, technological innovations, and its future prospects. Stay tuned as more updates and exciting advancements occur within this fascinating field!

FAQ:

- Q: What is aerospace PCB assembly?

A: Aerospace PCB assembly refers to the process of soldering components onto printed circuit boards (PCBs) specifically designed and manufactured to meet the rigorous standards and requirements of the aerospace industry. - Q: How are aerospace PCBs different from typical PCBs?

A: Aerospace PCBs are built to withstand extreme conditions like high and low temperatures, high pressure, and high vibrations. They are also designed with a higher focus on reliability and longevity to ensure safety in critical applications. - Q: What are the standard materials used in aerospace PCBs?

A: Typically, high-quality FR-4, polyimide, ceramic, and Teflon are used as base materials for aerospace PCBs due to their superior heat resistance and mechanical strength. - Q: Are there certifications required for aerospace PCB assembly?

A: Yes, most aerospace PCB assemblies must comply with aerospace standard certification like AS9100. - Q: What type of equipment is used for aerospace PCB assembly?

A: High-tech automated equipment such as pick-and-place machines, high-speed chip shooters, reflow ovens, etc., are used for the assembly process to ensure precision and quality. - Q: What kind of applications do aerospace PCBs have?

A: Aerospace PCBs are used in various applications like flight control systems, navigation systems, power supplies, communication systems, and more. - Q: What are the testing procedures involved in aerospace PCB assembly?

A: Extensive testing like Automated Optical Inspection (AOI), X-ray Inspection, In-Circuit Test (ICT), and Functional Circuit Testing are performed to ensure the reliability and functionality of the PCB. - Q: Does size matter in aerospace PCB assembly?

A: Yes, as components need to fit into compact spaces in aerospace applications, miniaturization in PCB assembly is crucial. Hence, high-density interconnect (HDI) boards are commonly used. - Q: Why is quality control crucial in aerospace PCB assembly?

A: Quality control is crucial due to the critical nature of applications. Any faults or failures can lead to catastrophic outcomes. - Q: Does aerospace PCB assembly require special safety measures?

A: Yes, due to the sensitive components and high standards involved, special safety measures such as ESD-safe workplaces and ESD-safe packaging are followed.