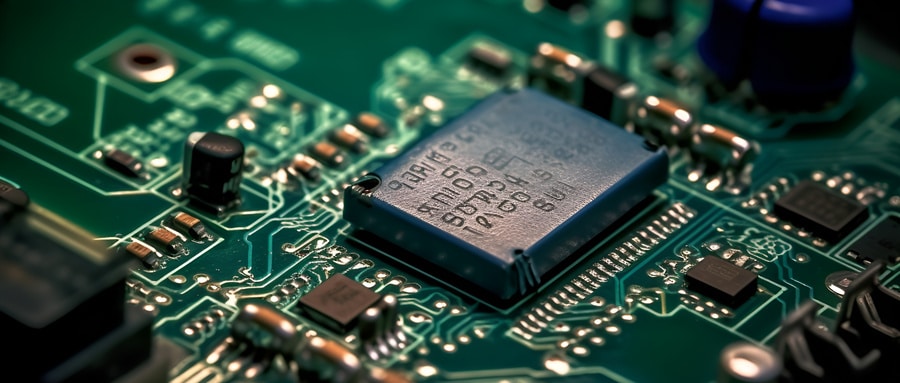

4-Layer PCB Stackup Design: Exploring the Benefits and Considerations

Implementing a 4-layer PCB stackup design can dramatically enhance the performance and functionality of electronic projects. Here, we explore its many advantages while outlining key considerations for successful implementation.

Advantages of a 4-Layer PCB Stackup Design

1. Improved Signal Integrity: A 4-layer stackup design offers enhanced signal integrity compared to 2-layer designs, due to dedicated power and ground planes which help reduce noise interference and interference-induced interference; this results in improved signal quality as well as system performance.

2. Decreased Electromagnetic Interference (EMI): Separating power and ground planes in a 4-layer stackup design helps minimize electromagnetic interference (EMI). The ground plane serves as an effective shield, minimizing chances of crosstalk or electromagnetic radiation – particularly important in high frequency applications where noise control is essential.

3. Design Flexibility: With a 4-layer stackup, there are more routing options and design flexibility. The extra layers provide additional space to route traces, simplifying routing requirements. They also enable complex designs involving high-speed signals, controlled impedance traces and differential pairs to be implemented successfully.

4. Improved Power Distribution: By employing dedicated power and ground planes on a 4-layer stackup design PCB, power distribution throughout is greatly enhanced, leading to reduced impedance on dedicated planes for better voltage drop reduction and reliable supply to critical components.

5. Ease of Manufacturing and Assembly: A 4-layer stackup design simplifies manufacturing and assembly processes. By providing separate power and ground planes, separation helps mitigate production issues such as solder bridging or short circuiting while improving thermal dissipation for increased longevity and reliability of electronic systems.

Considerations When Implementing a 4-Layer PCB Stackup

1. PCB Size and Cost: Consider both the size and cost implications of designing with four layers in mind when making decisions to implement this type of stackup design. Having additional layers could increase fabrication costs but make sure that their benefits justify any associated expenses.

2. Layer Assignment and Placement: Careful consideration should be given when assigning layers in a 4-layer stackup design, including layer assignments and component placement. Utilizing power and ground planes effectively for power distribution and noise suppression are both key. Proper component routing helps avoid signal integrity issues.

3. Design Guidelines: In order to successfully implement a 4-layer stackup PCB board, adhere to the design guidelines provided by your PCB manufacturer. Pay particular attention to factors like minimum trace width and spacing requirements, via specifications, and copper pour requirements outlined by these guidelines. Adherence will help achieve optimal performance and manufacturing cost efficiency.

4. Signal Integrity Analysis: Conduct signal integrity analyses to detect and address potential signal integrity issues within a 4-layer stackup design. Assess parameters like impedance control, signal reflections and crosstalk in order to guarantee reliable transmission without errors.

5. Layer Stackup Material Selection: Select suitable materials for each layer in your stackup stackup by taking into account dielectric constant, thermal conductivity, signal propagation speed and dielectric constant. Collaborate with your PCB manufacturer in selecting materials that fulfill all design specifications for your specific design requirements.

By carefully considering these factors and capitalizing on the advantages of 4-layer PCB stackup design, you can enhance performance, signal integrity and manufacturing of electronic projects. The additional layers provide ample opportunities for efficient power distribution, reduced EMI emissions and enhanced design flexibility – making a 4-layer stackup an appealing solution for diverse applications.

FAQ:

- What is a 4-Layer PCB Stackup?

A 4-layer PCB stackup includes four layers of conductive material, typically copper, laminated together with layers of insulating material in between and around them. - Why choose a 4-Layer PCB Stackup?

4-layer PCBs offer more routing flexibility and noise reduction capabilities than 2-layer PCBs. They are more affordable than boards with more layers and provide sufficient complexity for many applications. - How is a 4-Layer PCB Stackup created?

These are manufactured by sandwiching two inner layers of copper with an insulating material in between, and then adding two outer layers of insulating material coated with copper. - What is the typical layout for a 4-Layer PCB Stackup?

A typical 4-layer PCB stackup from top to bottom is: Signal layer > Ground plane > Power plane > Signal layer. This configuration provides good EMC performance. - How does a 4-Layer PCB Stackup help with EMC?

The ground and power planes in a 4-layer PCB stackup provide a solid capacitive coupling and create a low-inductance path for returning signal currents, reducing electromagnetic emissions. - What is the impact of the thickness of 4-Layer PCB Stackup on its performance?

The thickness of the PCB affects the impedance of the board, which may be essential depending on the specific application. Manufacturers typically offer different thicknesses to choose from. - What applications are optimal for a 4-Layer PCB Stackup?

They are often used in applications where size and weight restrictions are present. This includes, but is not limited to, digital and analog systems, power distribution boards, and moderate complexity circuitry. - What precautions need to be taken while designing a 4-Layer PCB Stackup?

It’s important to follow good design practices, like adequate spacing between components and avoiding sharp angles in traces, among others. It’s also critical to consider thermal management and EMC requirements. - What’s the process to order a 4-Layer PCB Stackup?

The process is generally the same as ordering other types of PCBs. The design files need to be sent to the manufacturer who will then review them and manufacture the boards based on the provided specifications. - What are the cost considerations for a 4-Layer PCB Stackup?

While a 4-layer PCB stackup is more expensive than a 2-layer due to the added complexity, it is generally cheaper than PCBs with more layers. The cost will also vary depending on the chosen materials, board size, and order quantity.