Unleashing the Potential of LED PCB Board: Advancements in Lighting Technology

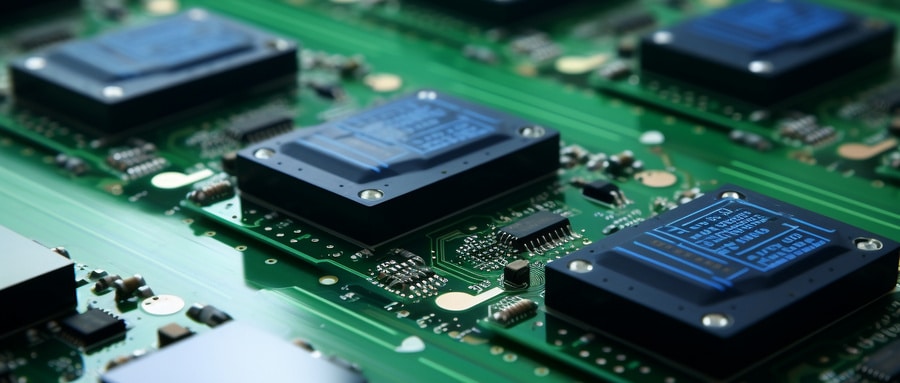

LED PCB Boards (Light-Emitting Diode Printed Circuit Boards) are at the core of modern lighting solutions, hosting LEDs that transform our illuminated world gradually. This article offers insight into their intricate layers – their workings, advantages, applications and future prospects – giving a full view of these indispensable components of modern lighting solutions.

1. Unraveling LED PCB Boards:

LED PCB Boards are constructed by attaching light-emitting diodes (LEDs) to a circuit board, depending on their application. Depending on this choice of material – aluminum, copper, or FR-4 can all have distinctive advantages; with aluminum typically being the go-to choice due to its exceptional thermal conductivity properties.

2. Advantages of LED PCB Boards:

LED PCB Boards boast several key advantages over their competitors. Their energy efficiency and long lifespan–two fundamental aspects of LEDs–are exceptional, and their superior thermal conductivity–such as aluminum’s high thermal conductivity–ensures longevities and reliability for these LEDs.

3. Diverse Applications of LED PCB Boards:

LED PCB Boards are used in a wide variety of lighting applications ranging from domestic household, automobile, street lighting and specialty applications such as horticulture and medicine. Their widespread application can also be seen by their presence backlit screens of devices like mobile phones and laptops – further evidence of their versatility.

4. Challenges and Solutions:

LED PCB Boards present numerous challenges for designers and engineers alike, including managing heat emitted by LEDs and producing high-power output without compromising lifespan or light quality. Multilayer PCBs with higher thermal conductivity materials like Aluminum or Copper help address such concerns.

5. Future of LED PCB Boards:

The future for LED PCBs looks exceptionally bright thanks to developments like smart lighting and IoT integration. Furthermore, advances in materials and manufacturing processes should enable more compact yet powerful boards with greater cost-efficiency.

Conclusion: mes With energy-efficiency revolution on the rise, LED PCBs prove invaluable as the foundation upon which LEDs rest. Their longevity, adaptability, and wide variety of applications make them essential in shaping future LED technology development. Furthermore, understanding their place within this landscape helps us appreciate their profound illuminating transformation that promises great things in our collective future.

FAQ:

- What is an LED PCB Board?

An LED PCB Board is a Printed Circuit Board specially designed for mounting and operating Light Emitting Diodes (LEDs). These can range from simple single-LED circuits to complex arrays of LEDs in lighting solutions. - What material is usually used for LED PCBs?

Besides the standard FR4 material, metal core PCBs, especially aluminum PCBs, are frequently used for LED applications due to their ability to disperse heat effectively, extending the lifespan of the LEDs. - How does an LED PCB function?

An LED PCB operates by providing the appropriate electrical connections to power the LEDs, along with appropriate resistors and power supply components. The design of the PCB will ensure that the LEDs are provided with the correct current and voltage levels to function optimally. - Can I design my own LED PCB?

Absolutely. Designing your own LED PCB can be beneficial in creating custom lighting solutions. You will require PCB design software and a basic understanding of the principles of electronic circuit design. - What software can I use to design an LED PCB?

There are many software options available for designing PCBs, including Eagle, KiCAD, and Altium Designer. These tools are powerful, and provide you with the freedom to create simple or complex LED circuits depending on your needs. - What power supply do I need for my LED PCB?

The necessary power supply for your LED PCB varies depending on the number and types of LEDs on the board. Voltage can range from a few volts for a single LED up to dozens of volts for arrays. - Can I use a microcontroller with my LED PCB?

Yes, you can. Microcontrollers are used in many LED PCB designs, especially when dealing with intelligent LED displays. They can provide you with the ability to control individual LEDs, sequences, or the entire display. - How do I solder LEDs onto a PCB?

LED soldering is similar to standard PCB component soldering: ensure your PCB and LEDs are clean, position the LED properly on the board, then melt the solder to create an electrical connection between the board and the LED’s leads. - What are the advantages of an LED PCB?

LED PCBs provide many benefits, including efficient thermal distribution, reduced energy usage, extended LED life, and the capacity to incorporate multiple LEDs on one panel. - What are some common applications of LED PCBs?

Common applications for LED PCBs are seen in various sectors including automobile lighting, flashlights and torches, street lighting, electronic consumer goods, and industrial lighting solutions.