The Rising Popularity of Purple PCBs: A Colorful Revolution in Circuit Design

Purple Printed Circuit Boards Are Gaining Popularity: An Eye-Catching Revolution In Circuit Design

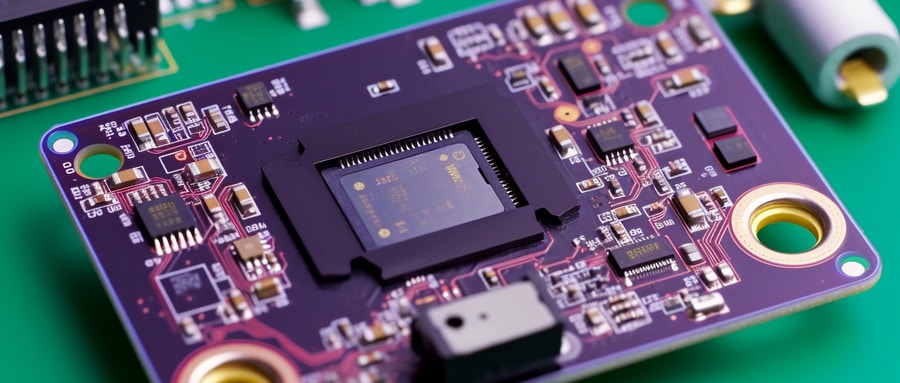

Green has long been the norm when it comes to printed circuit boards (PCBs). While green remains popular due to tradition and other practical considerations, recently there has been an unprecedented shift of color within electronics; Purple PCBs are leading this charge as innovators of change. This article delves deeper into why purple PCBs have gained so much traction within this field and explores why their rising preference among electronics professionals.

Why Does Color of PCBs Affect Performance?

Your first instinct may be to question why color matters for PCB design–does it enhance functionality or offer any specific advantages? But solder mask, which covers copper circuits to give the PCB its distinct appearance, plays an integral part of manufacturing and circuit design processes by providing both functional and aesthetic advantages.

The Emergence of the Purple Revolution

Green PCBs have traditionally dominated their field due to the ease of visual inspection for defects, being less expensive to produce and performing better in photosensitive processes. But purple PCBs are quickly making waves in the industry – but what exactly is driving their rise? Read on.

- Aesthetic Appeal: One reason behind the purple phenomenon may be aesthetic appeal: Purple PCBs give devices an eye-catching, vibrant, and premium aesthetic that has quickly become popular with tech enthusiasts and hobbyists.

- High-End Market Perception: Purple is often associated with luxury and premium goods. Electronics companies capitalize on this perception by including purple PCBs in their devices to give the impression they are high-end offerings in the market.

- Improved Visibility: Contrary to popular belief, purple solder masks often provide better contrast against copper tracks and silver solder, thus improving visibility of traces and aiding debugging processes.

- Unconventional Difference: In an industry where differentiation is key for success, using purple is an easy and effective way to stand out. It signals innovation and creativity.

Pushing Boundaries: Why Stick to Purple?

Why settle for just purple, you might ask? As the current trend towards moving away from conventional green has encouraged designers’ experimentation, black, blue, red and even yellow colors have all become viable choices when selecting your PCB color scheme based on brand positioning, functional requirements and aesthetic appeal.

Concluding: An Exciting Future Awaits

As we embark on the 21st century, the purple revolution in PCB design stands as a striking reminder that even color can spark innovation within electronics manufacturing. More than just a passing trend, this phenomenon represents the spirit of breaking boundaries and subverting norms–an invaluable lesson for those aspiring to breakthrough new ground in their fields of interest.

Purple PCB FAQ:

- Q: What is a Purple PCB?

A: A Purple PCB is simply a circuit board that has been colored purple on the exterior, usually through the application of a purple solder mask over the conductive tracks. - Q: How does the color of a PCB affect its performance?

A: The color of a PCB does not typically impact its electrical performance. It’s primarily an aesthetic choice or a means of brand identification. - Q: Who produces Purple PCBs?

A: Many PCB manufacturers can produce purple PCBs, though it is more common among certain manufacturers, such as OSH Park. - Q: Are purple PCBs common?

A: While less common than green or red PCBs, purple is a popular choice for PCBs, particularly for hobbyist and prototype boards. - Q: Does it cost more to have a purple PCB?

A: The cost can vary between manufacturers, but generally the color of the PCB has minimal impact on the price. - Q: Can I identify a PCB type or quality by its color?

A: No, color doesn’t indicate the PCB’s quality or type. It’s mostly used for aesthetics or branding. - Q: Can I order purple PCBs with different finishes?

A: Yes, you can usually order purple PCBs with standard finishes such as HASL, ENIG, OSP or others based on your needs. - Q: Can a purple PCB be used in commercial products?

A: Absolutely. Color does not impact the functionality of the PCB, and many commercial products use PCBs of various colors, including purple. - Q: Can the color of the PCB help in identifying tracks and components?

A: Yes, sometimes a certain color, like purple, can provide greater contrast making it easier to read the traces and labels on the PCB. - Q: How is the color added to the PCB?

A: The color of a PCB comes from the solder mask—the protective coating applied over the conductive copper tracks. Different pigments can be added to provide different colors.