Power PCB: A Deep Dive Into the Crucial Role of Printed Circuit Boards in Modern Electronics

In an ever-evolving digital world marked by rapid technological developments, printed circuit boards (PCBs) remain unsung heroes – they form the cornerstone of most electronic devices we rely on every day from smartphones and computers to home appliances – often going unrecognized but absolutely essential components in modern electronics. Unfortunately, their crucial role often goes overlooked; without them our smartphones, computers, and home appliances would no longer function like they do now. In this article we delve deeper into power PCBs; their intricate makeup; significance; multi-faceted applications across industries across electronics industry sectors.

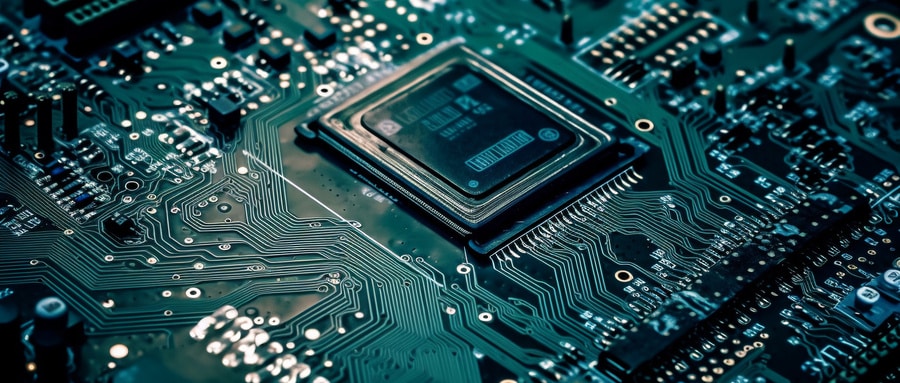

Unveiling the Microcosmic Marvel

PCBs – or printed circuit boards – are thin boards composed of fiberglass, composite epoxy or other laminate materials. Power PCBs go beyond their traditional counterparts by including power supply circuits to supply different voltage levels to other circuits on board without external power sources. As such, power PCBs form the backbone of all devices with integrated electronics, from household equipment to advanced medical devices and more.

Anatomy of a Power PCB

Understanding the inner workings of a power PCB requires an in-depth examination of its composition. A printed circuit board is composed of intricately-designed layers of copper traces which conduct power efficiently around its board to support all the various components embedded on it, providing reliable power distribution.

Design Principles and Components

Crafting a power PCB requires careful consideration of many variables. The level of complexity depends on its intended use; from electronic toys and toys for children to medical machinery. Board designs often incorporate components like resistors, capacitors, diodes, inductors, integrated circuits and subsystems that all play an essential part in producing its desired result.

Power PCB Applications: An Everyday Workhorse

Power PCBs demonstrate their flexibility across industries. From consumer electronics to medical devices, automotive and renewable energy sectors; power PCBs prove their worth across industries. Their high endurance and adaptability has seen them penetrate virtually every electronic system in today’s modern society; thus attesting their importance.

An Ever-Evolving Future

As we transition toward an increasingly digital future, our need for power PCBs will increase exponentially. Traditional power systems impede innovation; energy-efficient and compact power PCBs emerge as solutions. Moving forward, expect power PCBs to usher in advancements in electronic devices that make life simpler and more interconnected for us all.

Each time we press a button, light an LED, or command an electronic device there lies an intricate web of power PCBs silently powering our digital revolution. By appreciating their role in everyday life, we can appreciate their contribution to modern living while better comprehending electronics from a fundamental level.

By offering an in-depth overview of Power PCBs and their many applications, this article explores complex engineering concepts elegantly while making them accessible for everyday readers.

Power PCB FAQ:

- What is a Power Printed Circuit Board?

A Power Printed Circuit Board refers to a printed circuit board utilized for routing power, implementing power control, or interfacing power elements in a device. They are often designed to handle higher current levels compared to regular PCBs. - How are Power PCBs different from regular PCBs?

Power PCBs are designed with special considerations like high current carrying traces, heat dissipation methods, and use of specific power components. Materials used are often chosen for their heat resistance and dielectric properties. - What materials are commonly used in Power Printed Circuit Boards?

Materials vary depending on application requirements. For higher power applications, materials with higher thermal resistance like metal core or ceramic are used, while, for lower power applications, standard FR-4 might be sufficient. - What should you consider when designing a Power PCB?

When designing a Power PCB, ensure your traces can carry the required current, consider the thermal management, add protection features like fuses or circuit breakers, and select the right components that can handle your power levels. - Why is Heat Dissipation important in Power Printed Circuit Board?

Excess heat could damage electronic components or even the board itself. Proper heat dissipation or thermal management ensures that the heat generated from high power components does not impact the circuit’s performance. - What are some ways to manage heat on a Power PCB?

Methods to manage heat include using heatsinks, cooling fans, thermal vias, or even designing the PCB with special materials like a metal core to help in thermal dissipation. - How does layout play a part in designing Power Printed Circuit Boards?

Layout plays a crucial part in designing Power Printed Circuit Boards. Power and GND traces should be wide enough for the current they carry; orientation of components should allow heat to escape efficiently, and the placement of power components should be done to prevent heat from affecting neighboring temperature-sensitive components. - What are some software tools which can aid in designing Power PCBs?

Design software like Altium, KiCAD, and Eagle often come with thermal, power distribution analysis tools, and DRC (Design Rule Checks) which can assist in designing Power PCBs. - How do you choose components for a Power Printed Circuit Board?

Component selection depends on the critical parameters of your application: Voltage levels, current requirements, operational frequency, and thermal considerations. Always select components with ratings higher than the anticipated maximum levels. - How can I ensure the power circuit and signal circuit in the same PCB do not interfere with each other?

Proper separation, adequate filtering, and grounding are often practiced. Separation avoids interference from electromagnetic fields generated by power flow. Filtering prevents noise from switching power supplies disturbing signal integrity. Good ground planning can reduce ground loops.