Copper PCB: Great potential for use in aerospace and defense applications

-Copper PCB: A Popular Choice for High-Quality Printed Circuit Boards

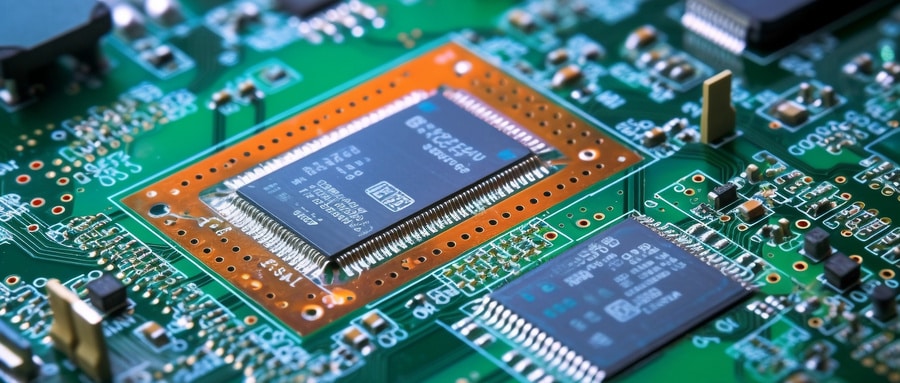

Printed circuit boards (PCBs) are essential components in modern electronic devices, providing a platform for the connection and control of electrical components. PCBs are made of various materials, but one of the most popular choices for high-quality PCBs is copper.

Copper PCBs offer numerous advantages over other materials due to the unique properties of copper. Copper has high electrical conductivity, thermal conductivity, and corrosion resistance. These properties make copper an ideal choice for PCBs that require high-speed signal transmission, power distribution, and heat dissipation.

Copper PCBs are created by laminating a layer of copper foil onto a substrate material, such as fiberglass or epoxy resin. The copper layer is then etched to create the desired circuit pattern, leaving the remaining copper as traces to connect components.

One of the primary advantages of copper PCBs is their high thermal conductivity. Copper has excellent heat dissipation properties, which means that heat generated by electronic components can be easily transferred away from the PCB. This helps to prevent overheating, which can damage components and reduce the overall lifespan of the device.

Copper PCBs are also ideal for high-speed signal transmission. Copper has high electrical conductivity, which means that signals can be transmitted quickly and efficiently across the PCB. This is especially important for devices that require high-speed data transfer, such as computer motherboards and networking equipment.

In addition to their functional benefits, copper PCBs also have a long lifespan and are highly resistant to corrosion. This makes them an ideal choice for devices that are exposed to harsh environments or require frequent use.

Copper PCBs are commonly used in a wide range of electronic devices, including smartphones, laptops, televisions, and medical equipment. They are also used in industrial applications, such as power supplies and motor control systems.

In conclusion, copper PCBs are an excellent choice for high-quality printed circuit boards. Their unique properties, such as high thermal conductivity and electrical conductivity, make them ideal for electronic devices that require fast signal transmission and efficient heat dissipation. Copper PCBs are also highly reliable and resistant to corrosion, making them an ideal choice for a wide range of applications.

– Exploring the potential of copper PCBs for use in aerospace and defense applications, such as in satellite communication systems and missile guidance systems.

Copper printed circuit boards (PCBs) have been widely used in electronic devices due to their excellent electrical and thermal properties. However, their potential in aerospace and defense applications has been largely unexplored until recently. With the increasing demand for high-performance electronics in these sectors, copper PCBs are now being considered as a promising alternative to traditional materials.

One of the main advantages of copper PCBs is their superior thermal conductivity. This property is crucial for aerospace and defense applications, where electronic devices are often subjected to extreme temperatures. It can dissipate heat faster than other materials, ensuring that the components stay within their safe operating range. This is particularly important for satellite communication systems, which must function in the vacuum of space and face temperature fluctuations ranging from -150°C to 150°C.

Another benefit of the board is their high electrical conductivity. This property allows for faster and more efficient transfer of electrical signals, which is essential for applications such as missile guidance systems. In these systems, time is of the essence, and any delay or interruption in signal transmission could lead to catastrophic consequences. Copper PCBs can help ensure that signals are transmitted quickly and accurately, reducing the risk of errors or malfunctions.

Copper PCBs are also highly durable and resistant to corrosion, making them ideal for use in harsh environments. In aerospace and defense applications, electronic devices are often exposed to moisture, salt, and other corrosive elements. Copper PCBs can withstand these conditions and maintain their performance over an extended period.

Furthermore, copper PCBs can be manufactured using a variety of fabrication techniques, including traditional etching and newer technologies such as laser ablation. This flexibility allows for the production of complex designs and miniaturized components, which are increasingly important in aerospace and defense applications.

In conclusion, copper PCBs hold great potential for use in aerospace and defense applications, particularly in satellite communication systems and missile guidance systems. Their excellent thermal and electrical properties, durability, and flexibility make them an attractive alternative to traditional materials. As technology continues to advance, copper PCBs are likely to play an increasingly important role in these critical industries.