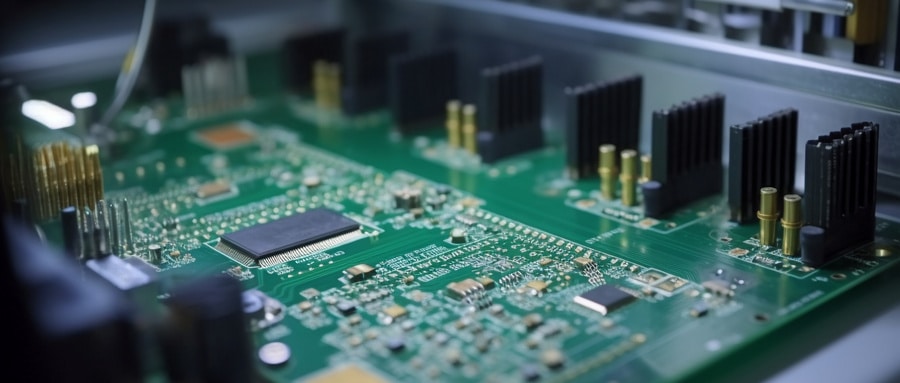

Blank PCB Board: The Unsung Hero of Electronic Devices

As we move further into the digital era, electronics have become an indispensable part of daily life. At the core of each electronic device ranging from complex industrial machinery to the simplest digital wristwatch rests an unsung hero of modern electronics: the blank PCB Board. Through this comprehensive guide we endeavor to unravel this unheralded component in detail.

Introduction of PCBs:

Before PCBs were invented, electronic circuit connections were made through point-to-point wiring which proved unreliable and often resulted in frequent failures and short circuits. Since PCBs’ invention, electronic components are soldered onto laminated boards etched with copper traces to form numerous electrical connections – creating miniaturization, automation and increased complexity among electronic devices.

Blank PCB: An Innovative Canvas in Electronics

Contrary to its name, a blank PCB doesn’t symbolize emptyness; rather it represents unbounded possibilities. Like an empty canvas ready for transformation by skilled circuit designers. Copper traces etched onto this blank PCB form the circuits which ultimately govern its operation and become part of any device created using it.

Types of PCBs:

- Single-Sided PCBs: These consist of one layer of substrate material coated on one side with metal plating – typically copper for excellent electrical conductivity.

- Double-Sided PCBs: These boards cover both sides of a substrate with metal, featuring holes for connecting circuits on one side to those on the other.

- Multi-Layered PCBs: As their name suggests, multi-layered PCBs feature multiple substrate layers separated by insulation. They’re ideal for complex electronic circuits requiring more space and organization – for instance in computers and satellite systems.

Innovation and Sustainability:

Over the years, the PCB industry has witnessed tremendous development and advancement. Thanks to flexible PCBs that bend without losing functionality, wearable technology and foldable tech have become more advanced and accessible than ever.

PCB manufacturers are increasingly turning towards eco-friendly materials and processes as part of their efforts to reduce electronic waste.

Purchase and Use of Blank PCBs:

No matter your level of experience in PCB design or manufacturing, understanding its specifications and quality are of vital importance for hobbyists, students and industry professionals. Specific points to keep in mind include board thickness, copper thickness, material type and edges quality.

As we progress into the future, blank PCB boards become even more important. From AI technology and green energy solutions to space explorations, the electronics industry provides plenty of room to innovate and create. Blank PCBs remain at the center of this exciting journey bringing our digital dreams into fruition.

By understanding this integral component’s functions, we not only unlock the magic behind everyday devices but expand our capacity for creativity, invention, and exploring the vast potential of electronic world.

Blank PCB Board FAQ:

- What is a Blank PCB Board?

A blank PCB board, or substrate, is a non-conductive material, typically fiberglass, used as a base to support electronic components that will be assembled onto it. It’s typically copper-clad and can range from single-sided to multi-layer designs. - How are Blank PCB Boards made?

The production process begins with a base material, usually a glass fiber epoxy board. A thin layer of copper foil is laminated onto this base, then the layout of the circuit is printed onto the copper layer using a photomask, after which the unwanted copper is etched away. - What materials are used for Blank PCB Boards?

The main materials used for blank PCBs are FR4 and copper. FR4 is a grade designation for glass-reinforced epoxy laminate sheets, tubes, or rods, and is most commonly used due to its excellent insulating properties and stability under varying conditions. - How do you choose the thickness of a Blank PCB Board?

The thickness of PCB boards may vary depending upon their application. Most common thicknesses fall between 0.062 inches – 0.125 inches. The thickness is determined based on factors like the type of components used, the application for which the board is used, and electrical requirements. - Can anyone purchase a Blank PCB Board?

Yes, blank PCBs are widely available and can be bought by anyone. They can be found in local electronic component stores, online retailers, and from manufacturers in a range of sizes, shapes, thicknesses, and finishes. - How is a circuit made on a Blank PCB Board?

The layout of the circuit is transferred onto the blank PCB using a UV exposure process, and the exposed areas are then developed and etched in an acid bath to remove unwanted copper. - What is a Copper Clad Blank PCB Board?

A “copper clad” blank PCB board is a non-conductive substrate that has a layer of copper bonded to it, onto which electronic circuits can be etched. - What are the different types of Blank PCB Boards?

Blank PCB boards can come in different types depending upon the number of copper layers, like single-sided (one copper layer), double-sided (two copper layers), and multi-layer (three or more copper layers). - Is soldering required on a Blank PCB Board?

Yes, to connect the components to the board, soldering is typically required. The solder provides both electrical connectivity and mechanical strength to the assembly. - What is a Single Sided Blank PCB Board?

A Single Sided Blank PCB Board is the simplest and most used type of PCB. This type of board only has one layer of conductive material applied to one side of the board. Components are soldered onto the same side as the copper tracks.