Bare pcb board ceramic, did you know it has so many advantages?1 time to teach you

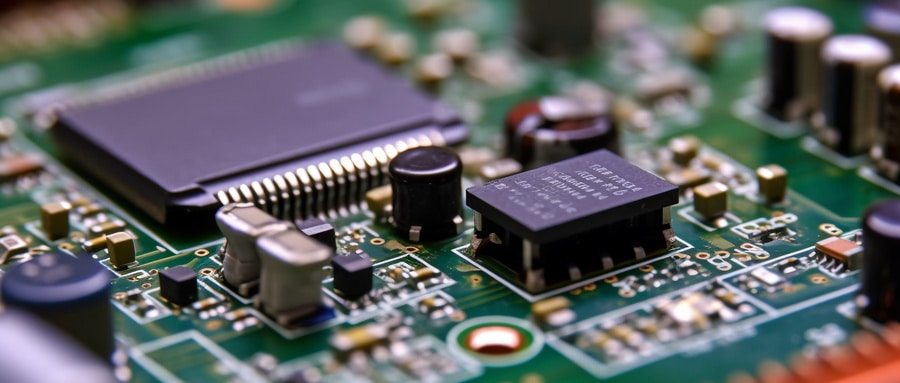

Bare PCB board ceramics are becoming increasingly popular in the electronics industry due to their durability, reliability, and versatility. These boards are made of ceramic materials, which offer excellent thermal and mechanical properties that make them suitable for a wide range of applications.

Bare PCB board ceramic are made by depositing a thin layer of ceramic material onto a metal substrate, such as aluminum or copper. The ceramic layer is then coated with a layer of copper, which is used to create the circuitry on the board. The result is a board that is lightweight, durable, and has excellent thermal conductivity.

One of the main advantages of using ceramic bare PCB boards is their ability to withstand high temperatures and harsh environments. Ceramic materials have a very low coefficient of thermal expansion, which means they do not expand or contract significantly when exposed to heat or cold. This makes them ideal for use in applications that require high-temperature operation, such as power electronics, aerospace, and automotive industries.

Ceramic bare PCB boards also offer superior mechanical strength and resistance to mechanical stress. They are less likely to crack or break under pressure, making them ideal for use in high-stress applications such as military and industrial equipment.

In addition to their excellent thermal and mechanical properties, ceramic bare PCB boards also offer superior electrical performance. They have a low dielectric constant, which means they can handle high-frequency signals without loss or distortion. This makes them ideal for use in high-speed data transmission applications such as telecommunications and computing.

Overall, ceramic bare PCB boards offer a range of benefits that make them an ideal choice for a wide range of electronic applications. Whether you need a board that can withstand high temperatures, mechanical stress, or high-frequency signals, ceramic bare PCB boards can provide the reliability and performance you need.

The future of bare pcb board ceramic

It is worth noting that ceramic PCBs are primarily used in high-power and high-temperature applications. These include power electronics, LED lighting, and aerospace applications. Because of their excellent thermal conductivity, they can dissipate heat efficiently, which is essential in these industries. In addition, ceramic PCBs have a low coefficient of thermal expansion, which makes them less susceptible to thermal stress.

One of the most significant advantages of ceramic PCBs is their reliability. They are less prone to damage from moisture and chemicals, and they have a longer lifespan than other types of PCBs. This makes them ideal for use in harsh environments.

However, there are some drawbacks to ceramic PCBs. They are more expensive than other types of PCBs, and they are more difficult to manufacture. This is because they require specialized equipment and expertise to produce. In addition, they are more brittle than other types of PCBs, which can make them more prone to cracking or breaking.

Despite these challenges, there is a growing interest in the future of ceramic PCBs. One reason for this is the increasing demand for higher power density and efficiency in electronic devices. Ceramic PCBs can handle higher currents and temperatures, making them ideal for use in high-power applications. In addition, they are compatible with a wide range of materials, which makes them versatile for various applications.

Another reason for the interest in ceramic PCBs is their potential for integration with other technologies. For example, researchers are exploring the use of ceramic PCBs in combination with additive manufacturing techniques, such as 3D printing. This could lead to new possibilities for designing and manufacturing complex electronic devices that are not possible with traditional manufacturing techniques.

In conclusion, while ceramic PCBs have been in use for several years, there is still a lot of potential for their future development. As technology advances, there will be new opportunities for ceramic PCBs to be used in high-power and high-temperature applications. With their excellent thermal properties and reliability, they will continue to be an essential component in the electronics industry.

FAQ:

1. What is a ceramic PCB?

2. What are the advantages of using ceramic PCBs over traditional PCBs?

3. What materials are used to make ceramic PCBs?

4. What are the different types of ceramic PCBs available?

5. What industries commonly use ceramic PCBs?

6. What are the temperature and thermal conductivity properties of ceramic PCBs?

7. How are ceramic PCBs manufactured?

8. What are the design considerations for ceramic PCBs?

9. How do you test ceramic PCBs for quality assurance?

10. What are the cost implications of using ceramic PCBs?