An Insightful Guide to PCB Mounting: Techniques, Best Practices, and Considerations

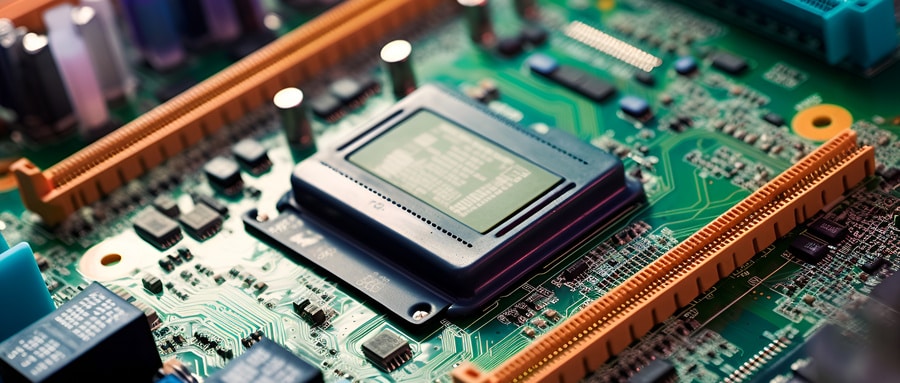

PCB mounting plays an integral part in ensuring product reliability and functionality, so its implementation must be handled carefully to achieve maximum performance and ensure optimal reliability. PCB, or Printed Circuit Board, serves as the heart and brain of electronics, so its proper mounting must be done efficiently for optimal results. In today’s article we’ll take an in-depth look at PCB mounting from start to finish!

1. An Overview of PCB Mounting Options

PCB mounting involves attaching the printed circuit board (PCB) to its respective housing or casing within an electronic device. It’s essential that this process goes smoothly as incorrect mounting of PCBs can lead to misalignments, short circuits, or even permanent damage of the board itself.

2. Techniques for PCB Mounting

Before we continue with PCB mounting, it is crucial that we understand its various techniques, which typically fall under two major categories: Surface Mount Technology (SMT) and Through-Hole Technology (THT).

2.1 Surface Mount Technology (SMT)

SMT (Surface Mount Technology) is the go-to method for mounting components onto PCBs, with manufacturers taking advantage of its compact designs to fit more components onboard. This process also results in less material being wasted for assembly.

2.2 Through-Hole Technology (THT)

THT (Through Hole Technology) is an age-old process in which component leads are inserted through pre-drilled holes on a PCB. Although more laborious and time-consuming than SMT, THT provides stronger mechanical bonds – making it ideal for components undergoing high amounts of physical stress.

3. Proven Strategies in PCB Mounting

Now that we understand various mounting techniques, let’s review some best practices that can ensure optimal PCB performance.

3.1 Placement of Components

Correct component placement is critical to avoid issues such as short circuiting or overheating, so carefully planning the layout of your PCB and positioning components accordingly is vital for optimal functional efficiency.

3.2 Prioritize Quality Control

Quality control should always be the top priority in PCB mounting, including regular inspections to ensure components are accurately placed and that the PCB is adequately cleaned.

4. Key Considerations in Mounting PCBs

Not only should best practices be followed when mounting a PCB, but other factors must also be taken into account to ensure its optimal operation.

4.1 PCB Material in Mind

When selecting the material of a PCB, material choice can play an integral part of its success and mounting techniques can vary accordingly.

Thermal Management

Effective thermal management is essential in order to prevent PCB overheating, which could damage individual components or worse, result in its malfunction and eventual failure.

5. PCB Mounting and Its Future Developments

PCB mounting technology continues to advance rapidly, opening up new techniques and methods. Staying abreast of these advancements is vital for anyone involved with electronics – hobbyists or professionals.

PCB mounting is a fundamental and complex aspect of electronics, and mastery of this art not only increases one’s technical skills but is key for device and product functionality.

So concludes our in-depth article on PCB mounting, hopefully giving you valuable insights to enhance your knowledge and capabilities in this exciting field of electronics. There’s much yet to learn, with more advances on their way – our journey has only just begun!

FAQ:

- Q: What is PCB mounting?

A: PCB mounting is the process of affixing a printed circuit board (PCB) to a housing or enclosure in a device. This is typically done to secure the PCB and protect it from damage. - Q: What methods are used to mount PCBs?

A: Common methods for mounting PCBs include using screws, standoffs, snap-in mounts, adhesives, or slotting the PCB into specially designed grooves in the enclosure. - Q: What are PCB standoffs?

A: Standoffs are small hardware pieces used to raise and secure the PCB away from the housing surface. They prevent short circuits by avoiding metal contact and allow for air circulation underneath the PCB. - Q: What are the advantages of screw mounting?

A: Screw mounting is sturdy and reliable, offering high resistance to shocks and vibrations. It’s a common method used for larger, heavier PCBs. - Q: Why use snap-in mounts for PCB mounting?

A: Snap-in mounts are quick, tool-free options that are integral to the enclosure. They allow for easy installation and removal of the PCB. - Q: How does adhesive PCB mounting work?

A: Adhesive mounting uses a strong adhesive to attach the PCB to the enclosure. This method is used when holes cannot be drilled into the PCB, but it can complicate PCB removal or replacement. - Q: What factors should I consider when choosing a PCB mounting method?

A: Factors to consider include the design and size of the PCB, the type of device and its housing, installation and removal needs, and environmental factors like shocks and vibrations. - Q: How important is the enclosure design in PCB mounting?

A: The enclosure design plays a crucial role in PCB mounting. It should accommodate the PCB’s size and shape, allow for necessary connections, and support the chosen mounting method. - Q: How can I ensure good thermal management when mounting my PCB?

A: Proper thermal management can be achieved through the use of heat sinks, thermal pads, or by designing the enclosure to promote airflow around and under the PCB. - Q: Can I mount multiple PCBs in one enclosure?

A: Yes, multiple PCBs can be mounted in one enclosure, usually by using standoffs and spacers to stack them, or by using separate mounting points or areas within the enclosure. Proper spacing should be ensured for heat dissipation and to avoid electrical interference.