What do you know about 3 step hdi pcb?

“Streamline Your Design with 3 Step HDI PCB Technology”

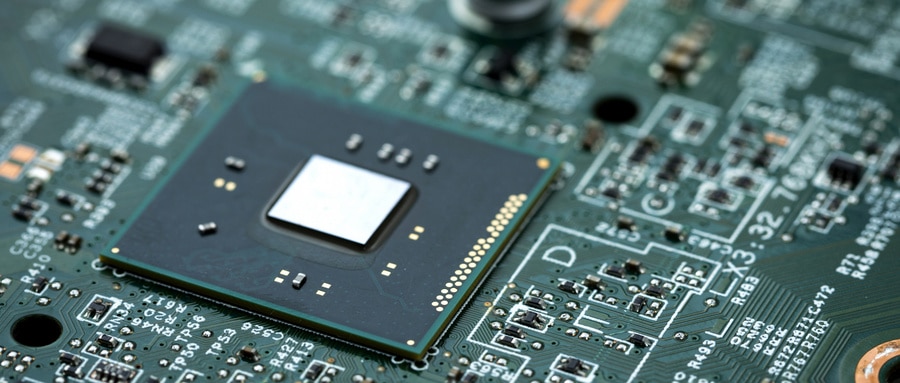

In the world of printed circuit boards (PCBs), High Density Interconnect (HDI) technology has become increasingly popular due to its ability to pack more circuitry into a smaller space. HDI PCBs allow for more complex and advanced electronic devices to be designed and manufactured, which is why they are widely used in industries such as aerospace, medical devices, and telecommunications.

HDI technology achieves its high density through the use of microvias, which are tiny holes drilled into the PCB that allow for multiple layers of circuitry to be stacked on top of each other. This allows for higher component density and smaller overall board size, making HDI PCBs ideal for applications where space is limited.

In addition to their compact size, HDI PCBs also offer improved signal integrity and reliability. With shorter signal paths and reduced electromagnetic interference, HDI PCBs can provide higher speed and more accurate signal transmission. This makes them ideal for high-performance applications such as data centers and telecommunications equipment.

Despite their many advantages, HDI PCBs can be more complex and expensive to manufacture than traditional PCBs. However, as demand for smaller and more advanced electronic devices continues to grow, the benefits of HDI technology are likely to outweigh the costs for many industries.

A 3 step HDI PCB is a type of HDI PCB that is made using a three-step process. This process involves building the PCB in three layers, with each layer having a specific function. The three layers are:

1. Core layer: This is the center layer of the PCB and acts as the foundation for the other two layers. It is made of a non-conductive material, such as fiberglass or epoxy resin, and has copper traces etched onto it to create the circuitry.

2. Prepreg layer: This layer is made of a fibreglass fabric that has been impregnated with resin. It is used to insulate the copper traces on the core layer.

3. Surface layer: This layer is the top layer of the PCB and is where the components are mounted. It is also made of a non-conductive material, such as FR-4 or polyimide, and has copper traces etched onto it to connect the components.

The 3 step HDI PCB process allows for more complex circuitry to be created in a smaller space. It also allows for more precise and accurate connections between components, which can lead to improved performance and reliability.

One of the main advantages of using a 3 step HDI PCB is its compact size. These PCBs can be designed to be much smaller than traditional PCBs, which is important in industries where space is limited. For example, in the medical device industry, where devices such as pacemakers and hearing aids need to be small and lightweight, a 3 step HDI PCB can be a perfect solution.

Another advantage of using a 3 step HDI PCB is its increased reliability. The use of multiple layers and precise connections between components means that there is less chance of a failure due to a loose connection or a short circuit. This is important in industries such as aerospace and defense, where reliability is critical.

In conclusion, the 3 step HDI PCB is a powerful tool for creating complex and advanced electronic devices. Its compact size and increased reliability make it a popular choice in industries such as aerospace, medical devices, and telecommunications. As technology continues to advance, it is likely that the use of HDI PCBs will become even more widespread, and the 3 step process will continue to be an important part of this trend.

FAQ:

1. What is HDI PCB?

2. What are the advantages of HDI PCB?

3. What are the different types of HDI PCBs?

4. What are the design considerations for HDI PCBs?

5. What are the manufacturing challenges for HDI PCBs?

6. What are the materials used in HDI PCBs?

7. How does HDI PCB differ from traditional PCB?

8. What are the applications of HDI PCB?

9. What are the benefits of using HDI PCB in high-frequency applications?

10. What are the testing and inspection methods for HDI PCBs?